LUMLE *

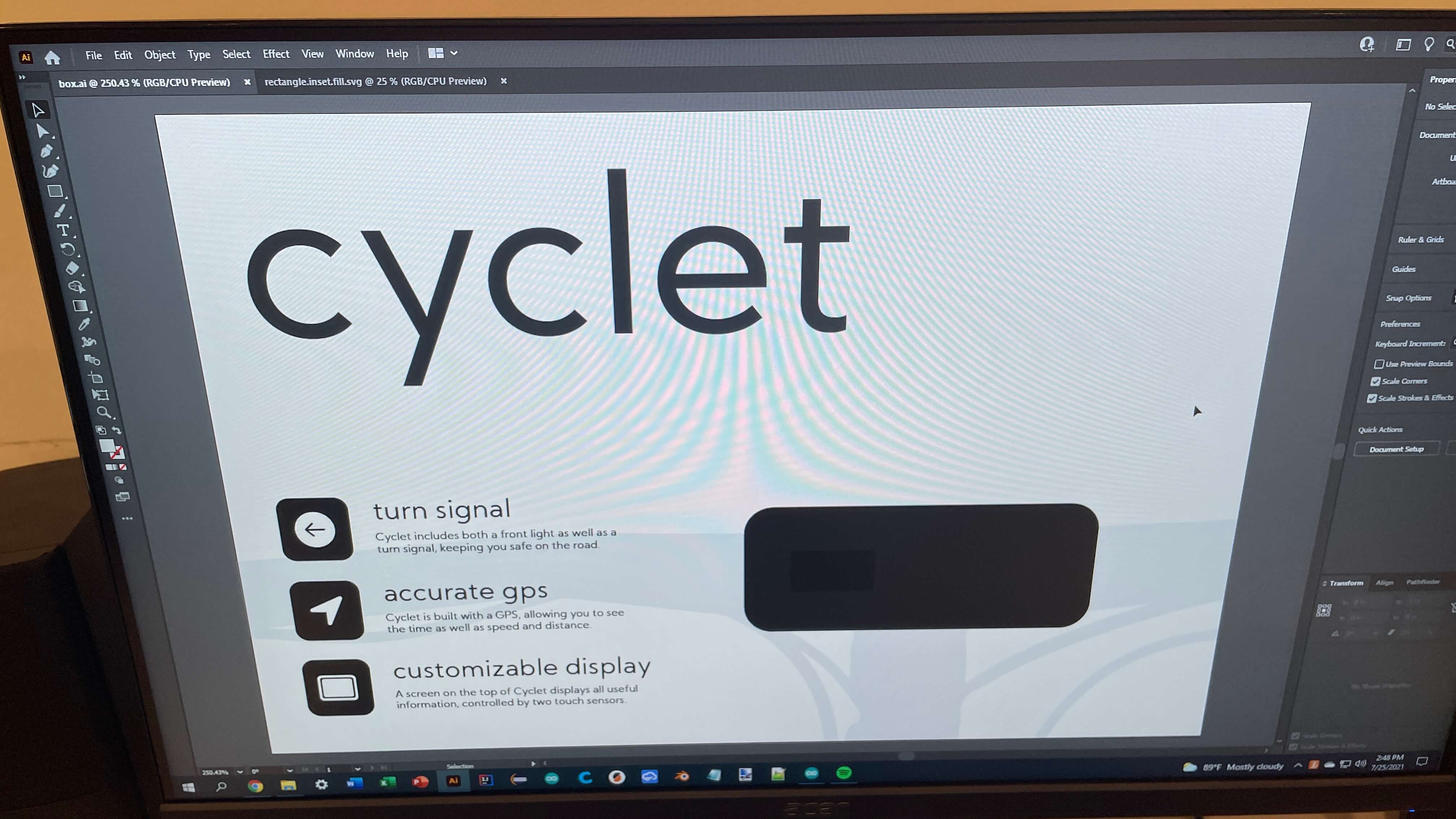

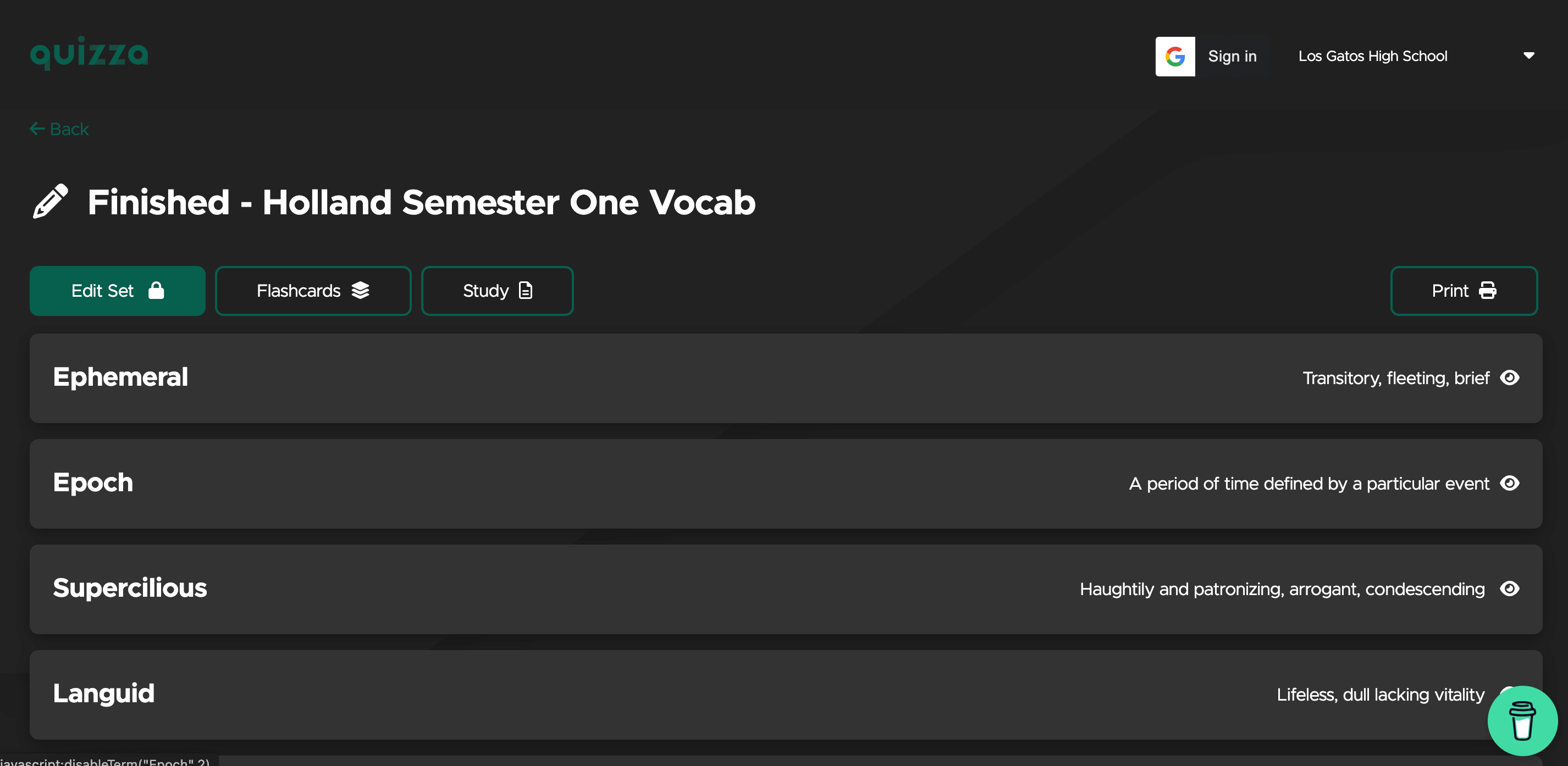

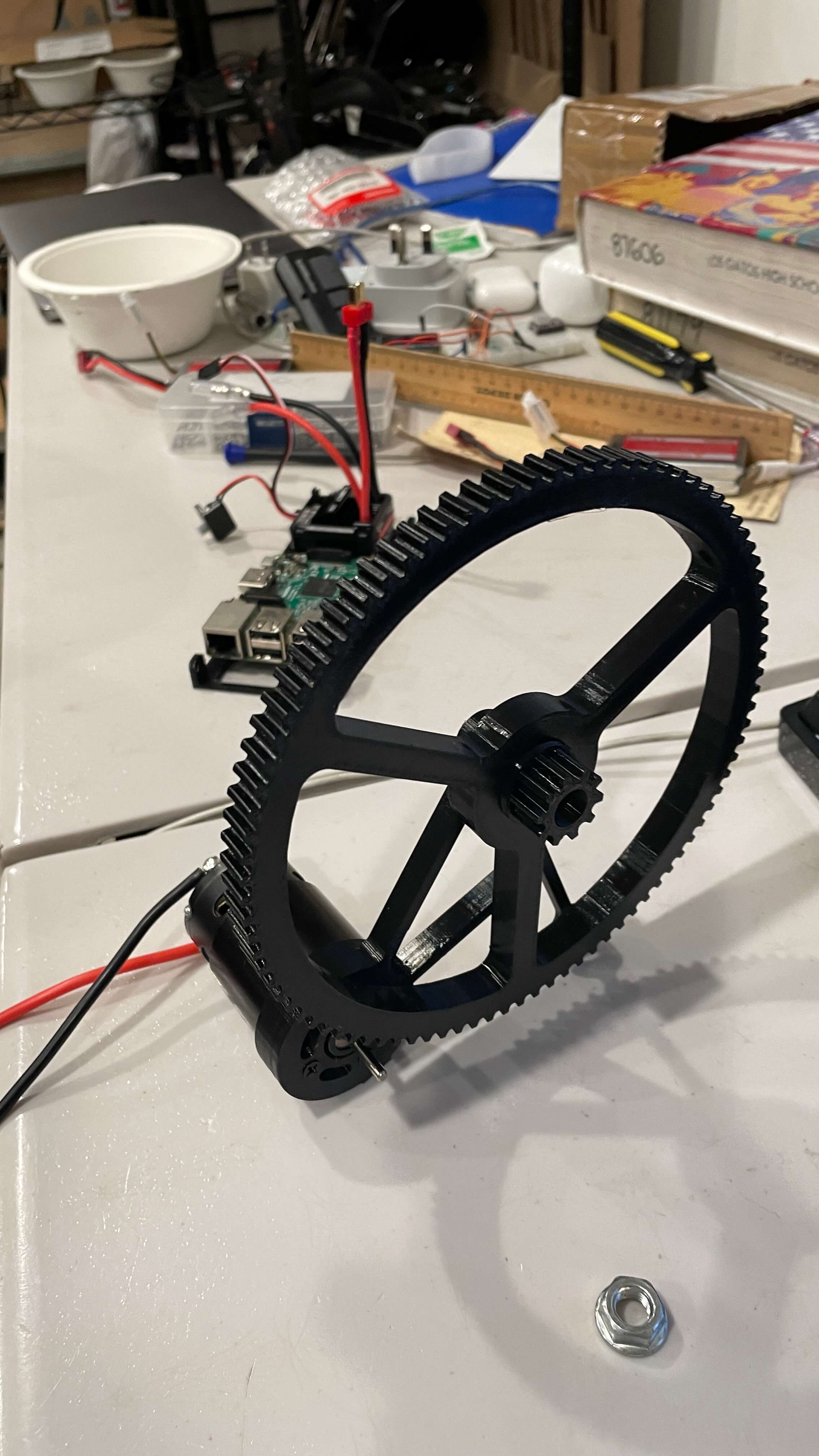

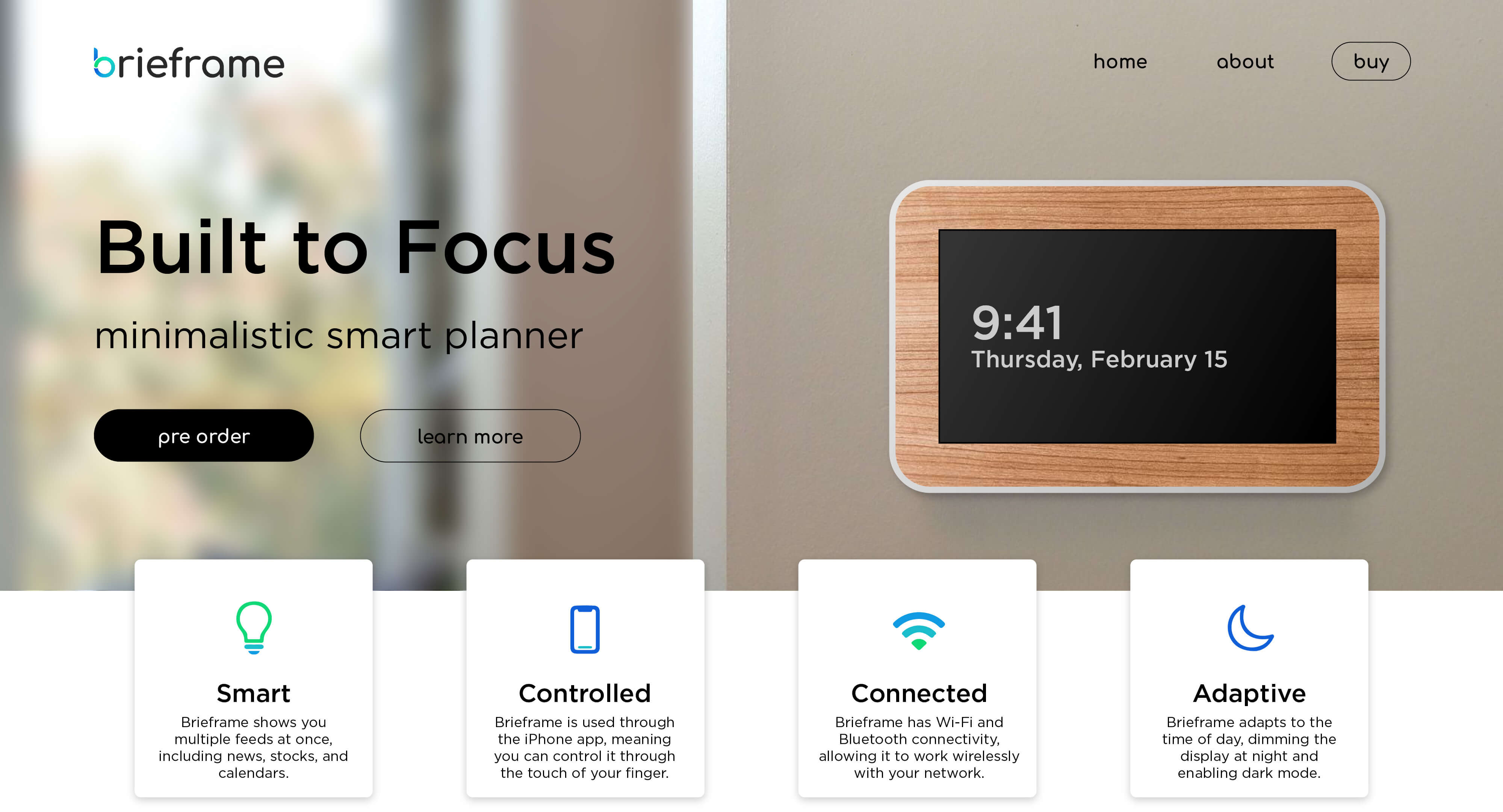

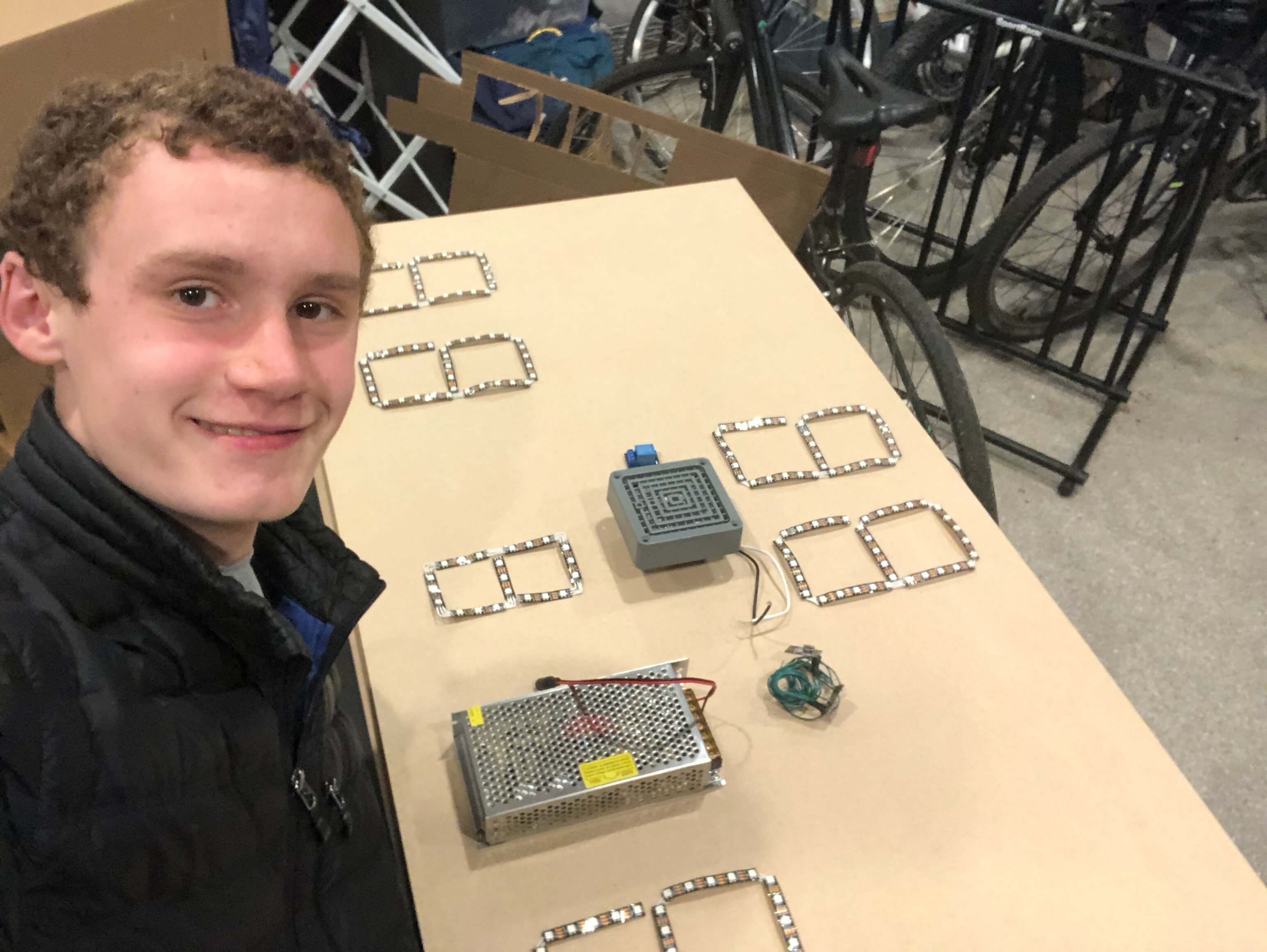

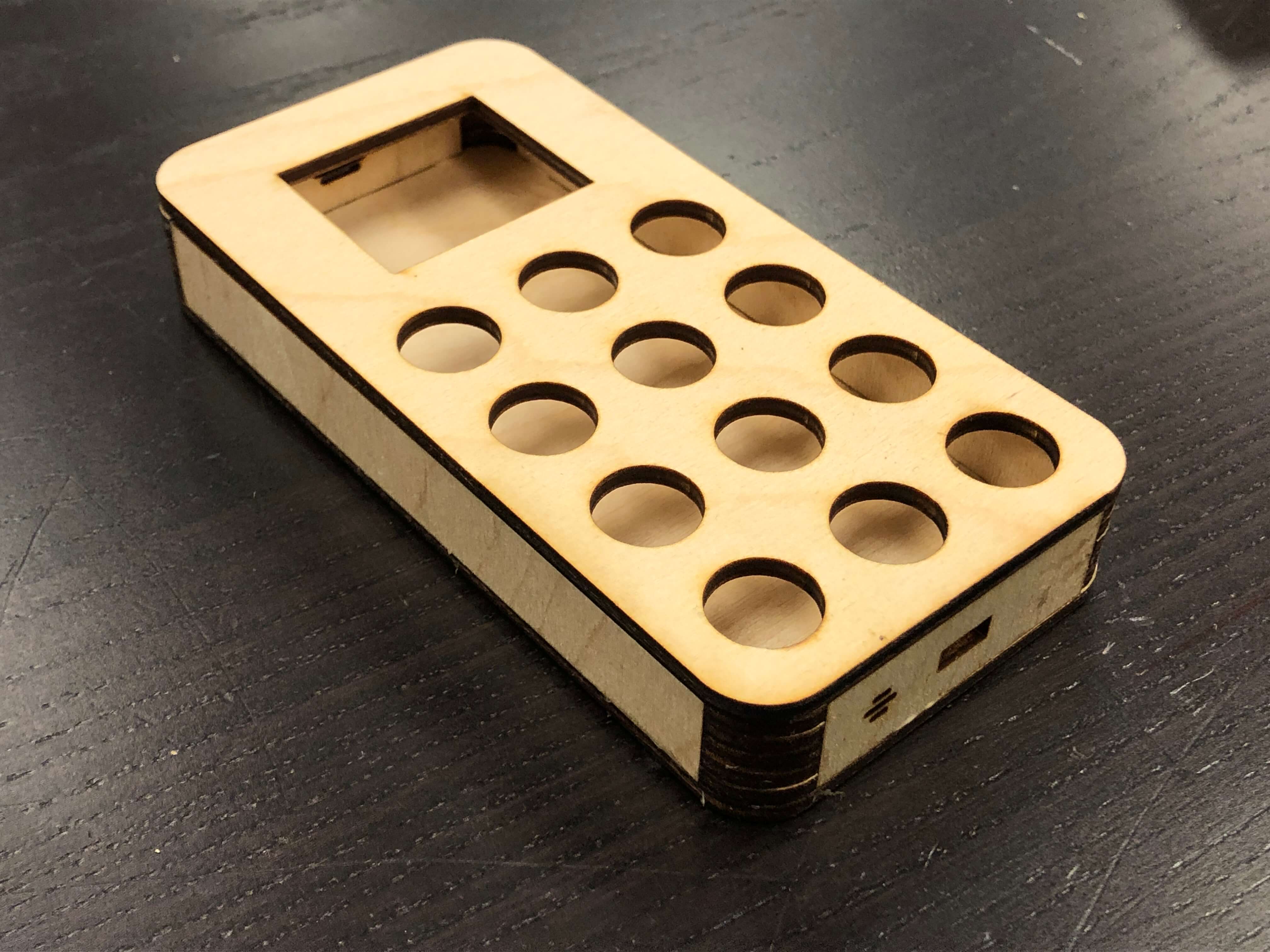

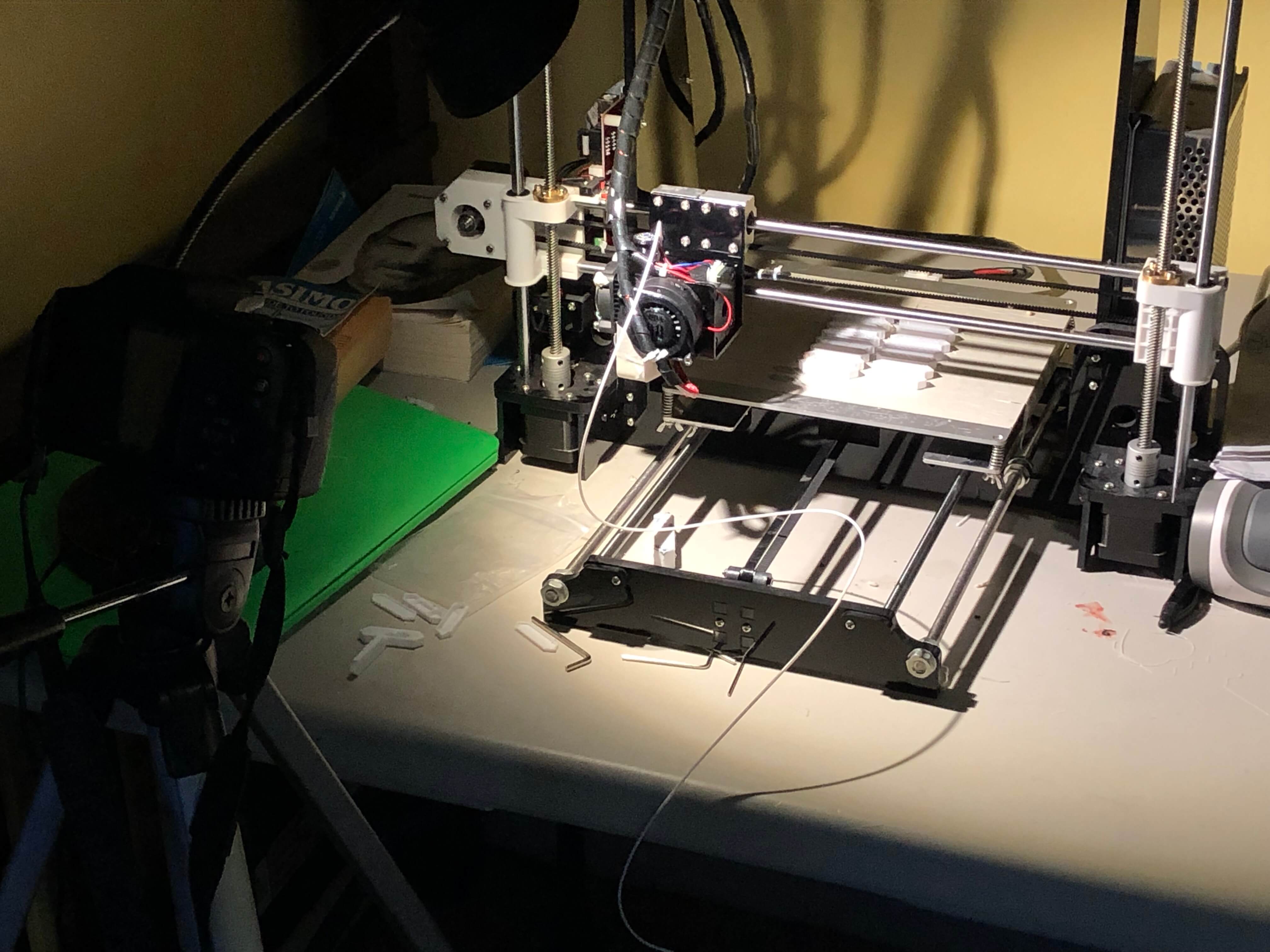

College time! To prepare to move into a dorm, I did what every aspiring college student does and looked up “top 50 college necessities” on WikiHow. One item that kept popping up was a calendar or planner, which was a big of a problem because I’d rather spend hours developing something to do it for me than to just take five minutes to do it myself. Lumle was born.

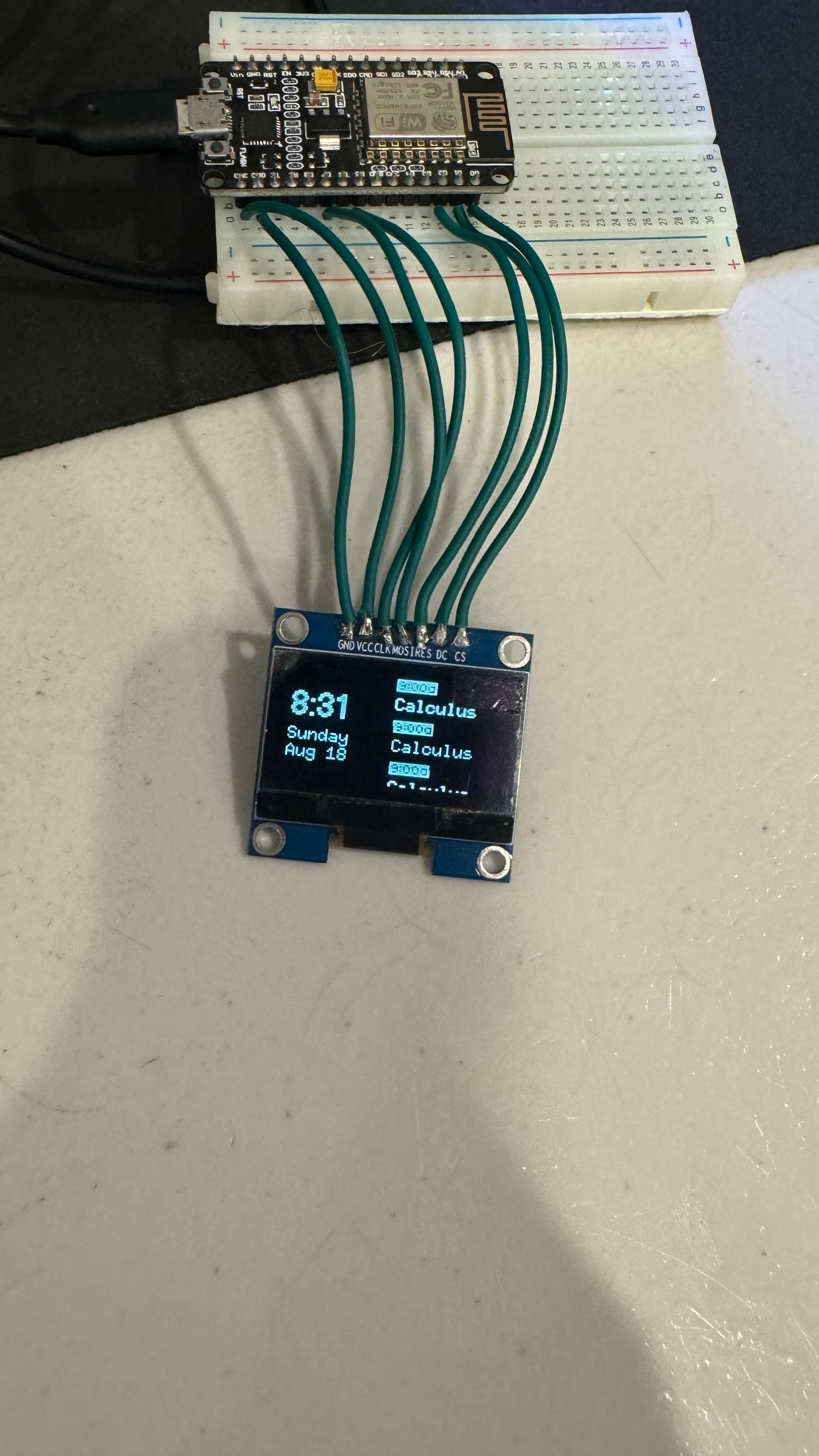

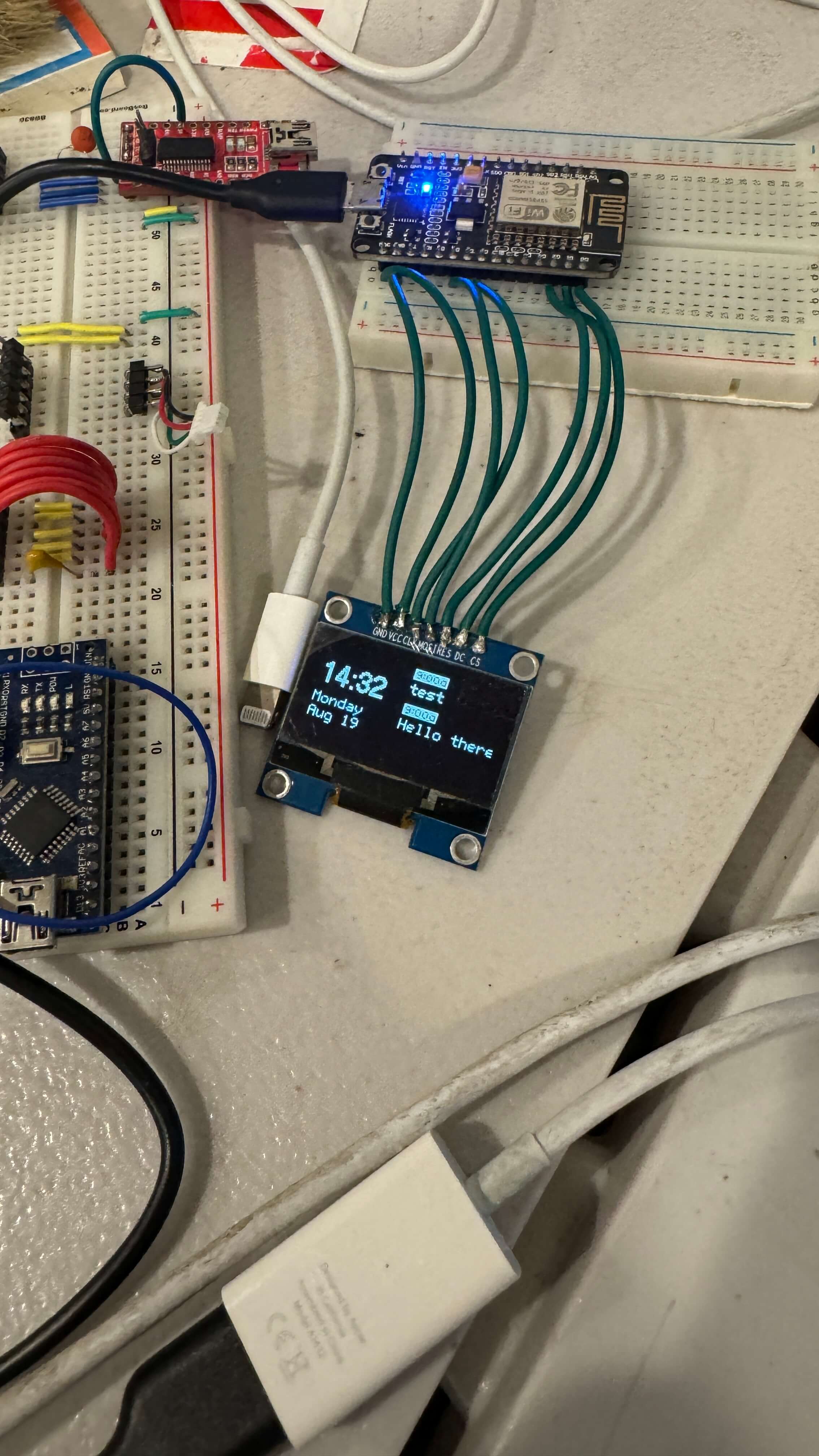

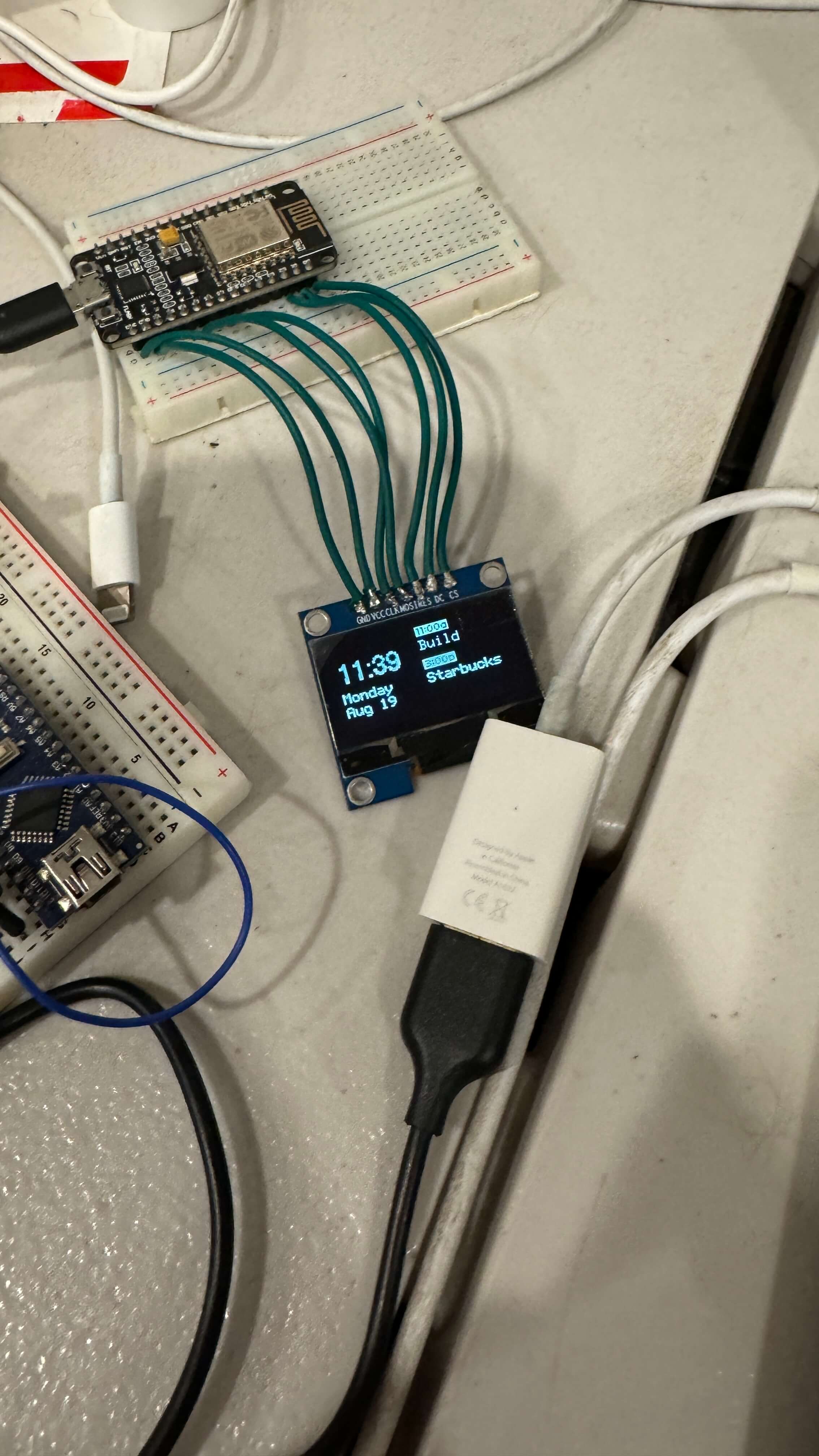

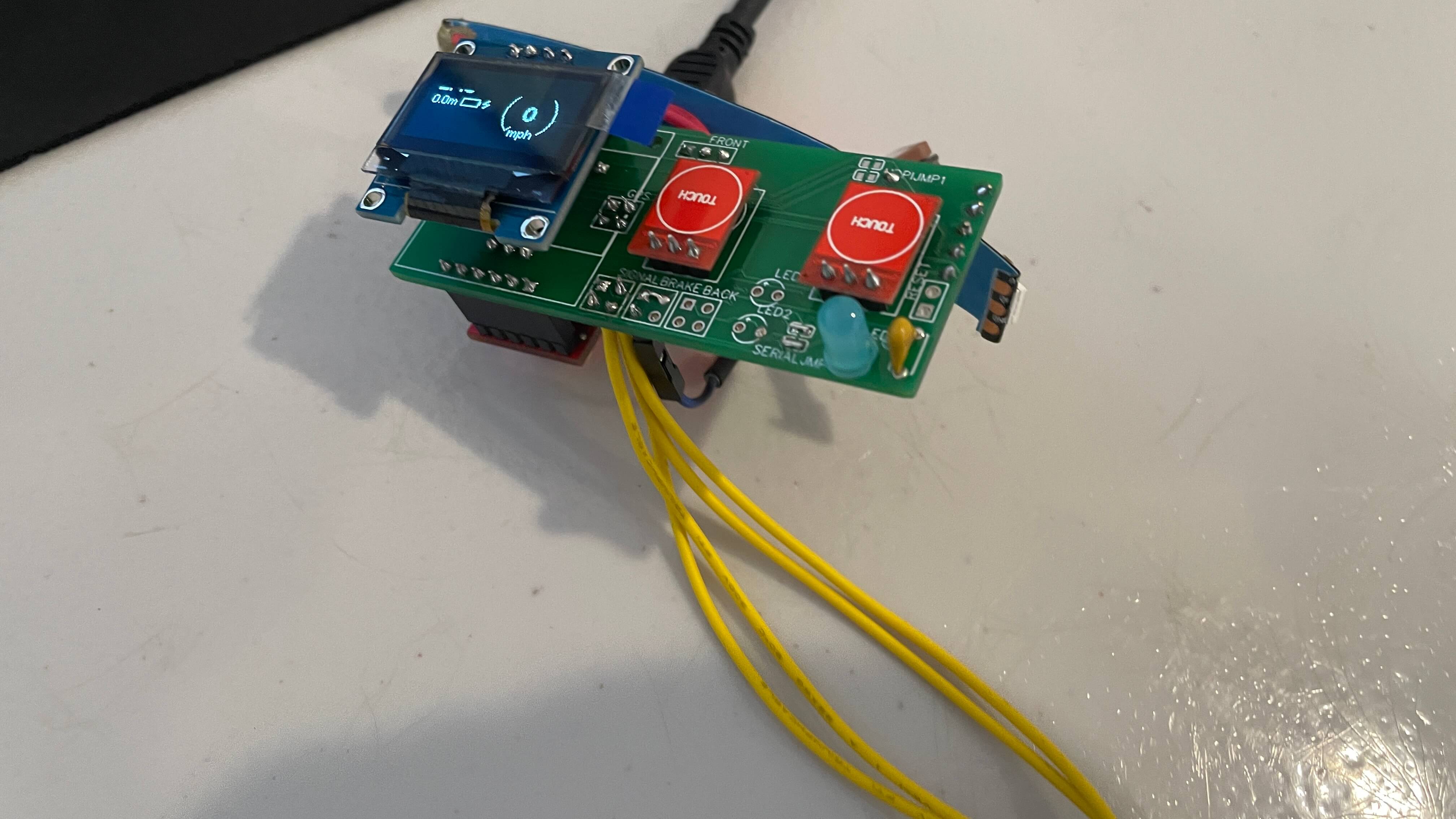

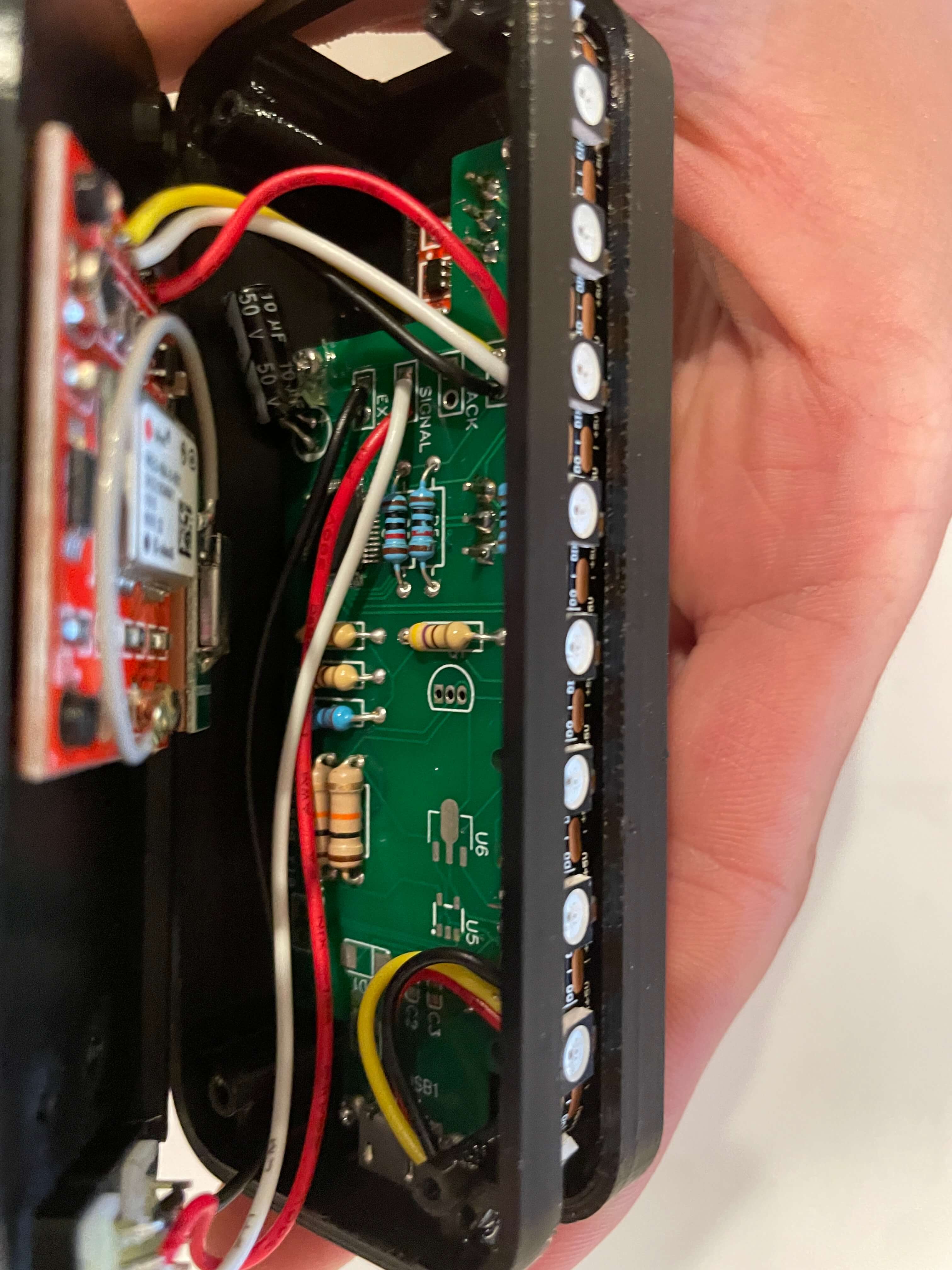

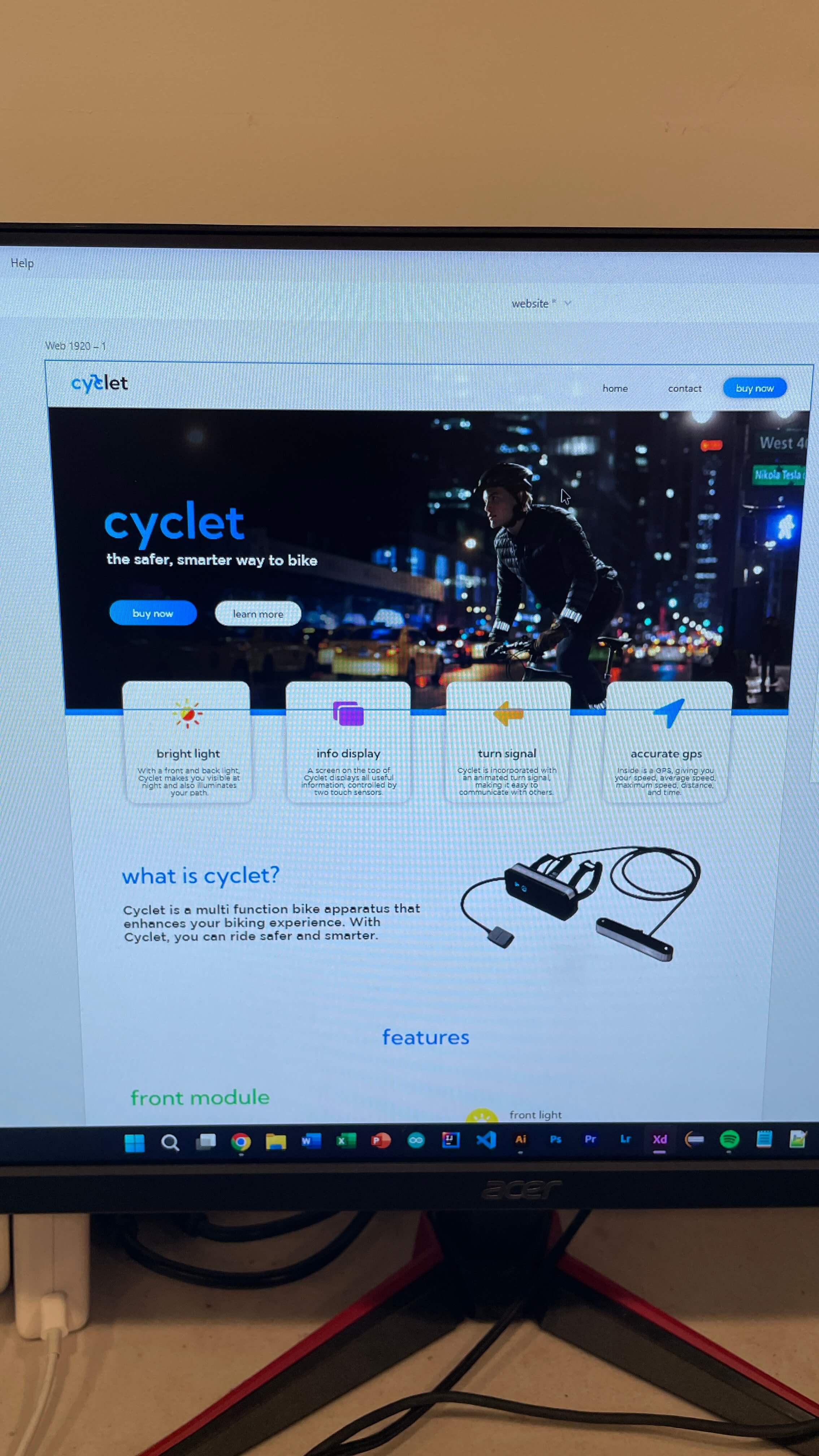

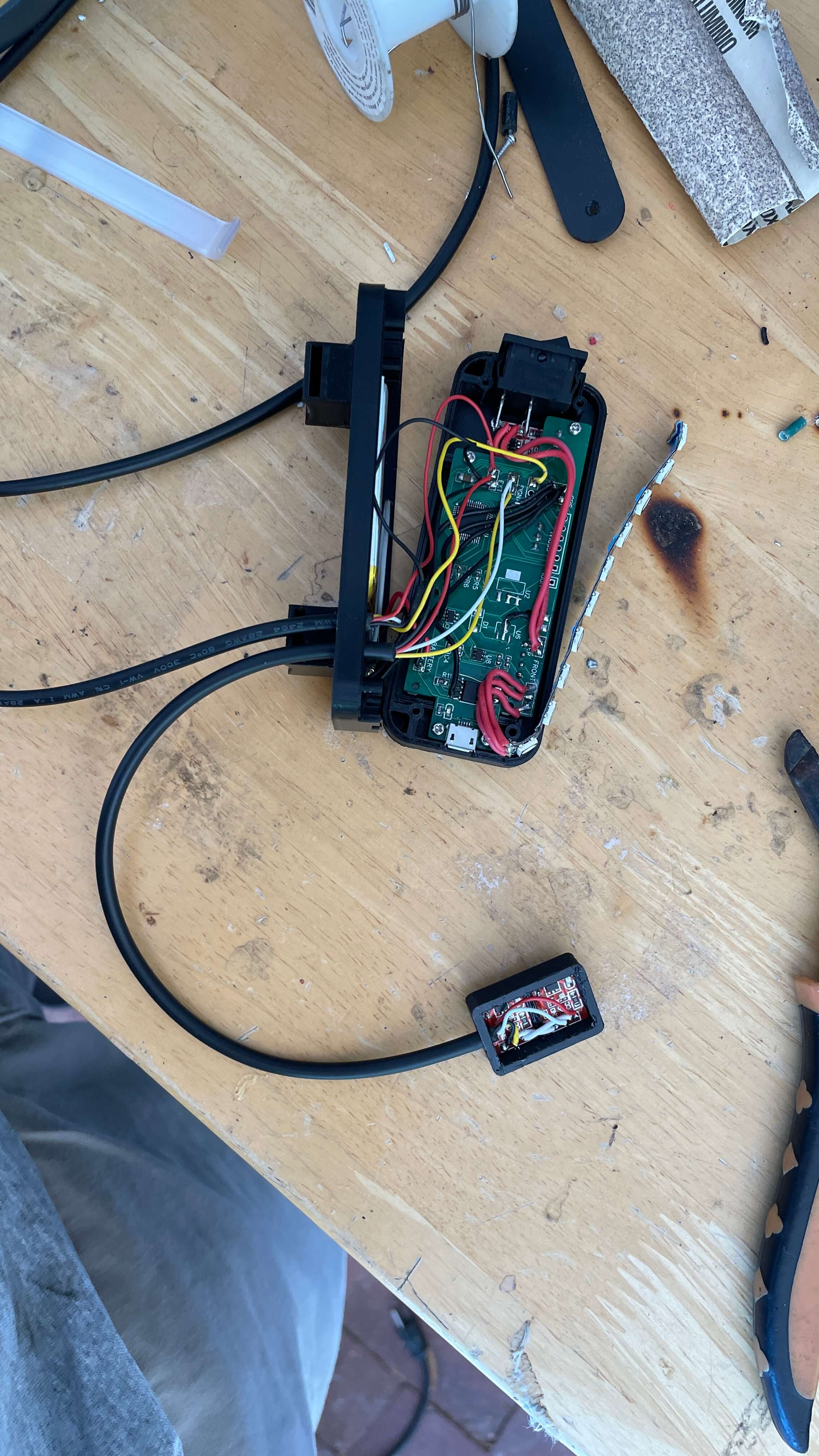

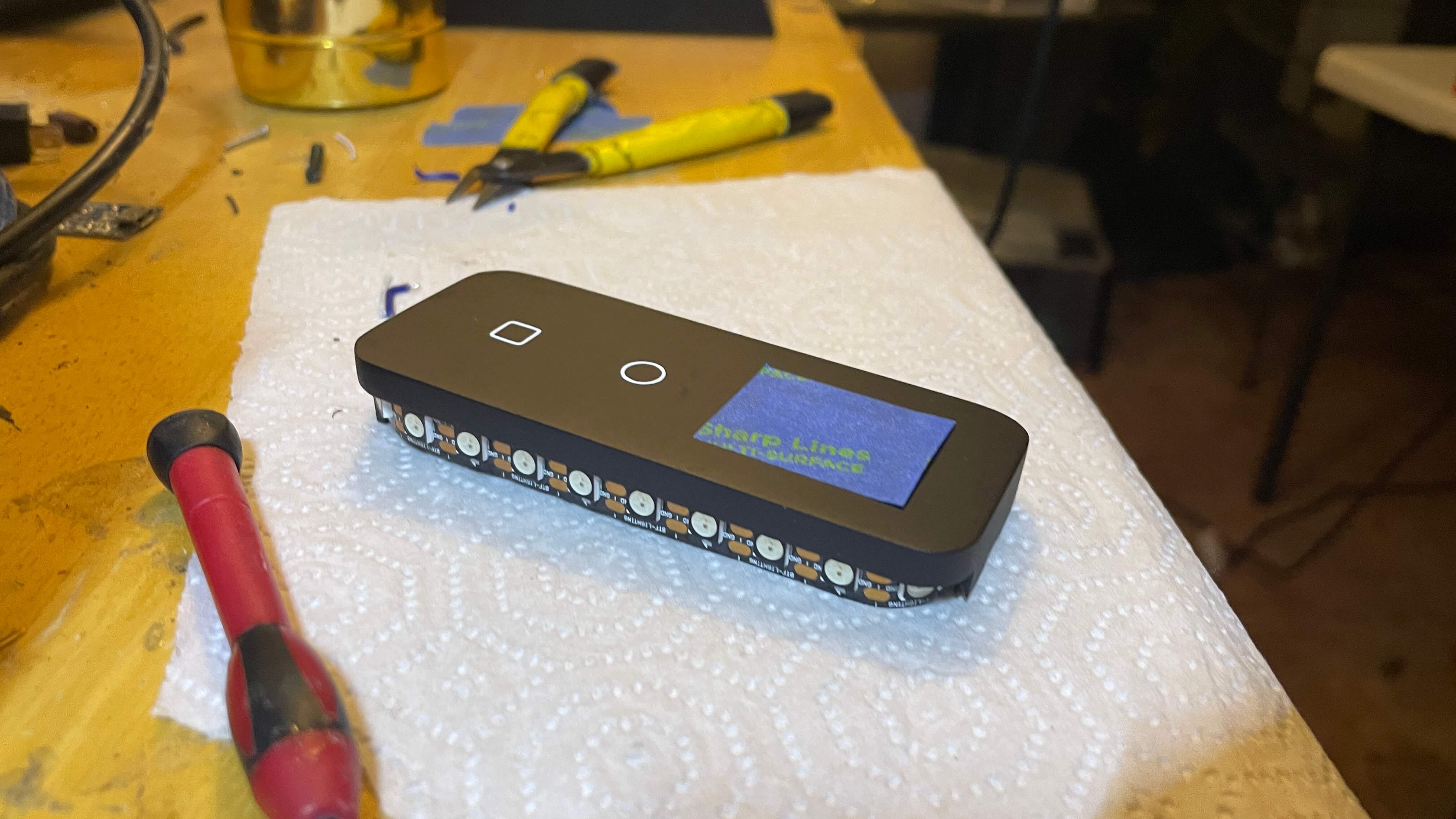

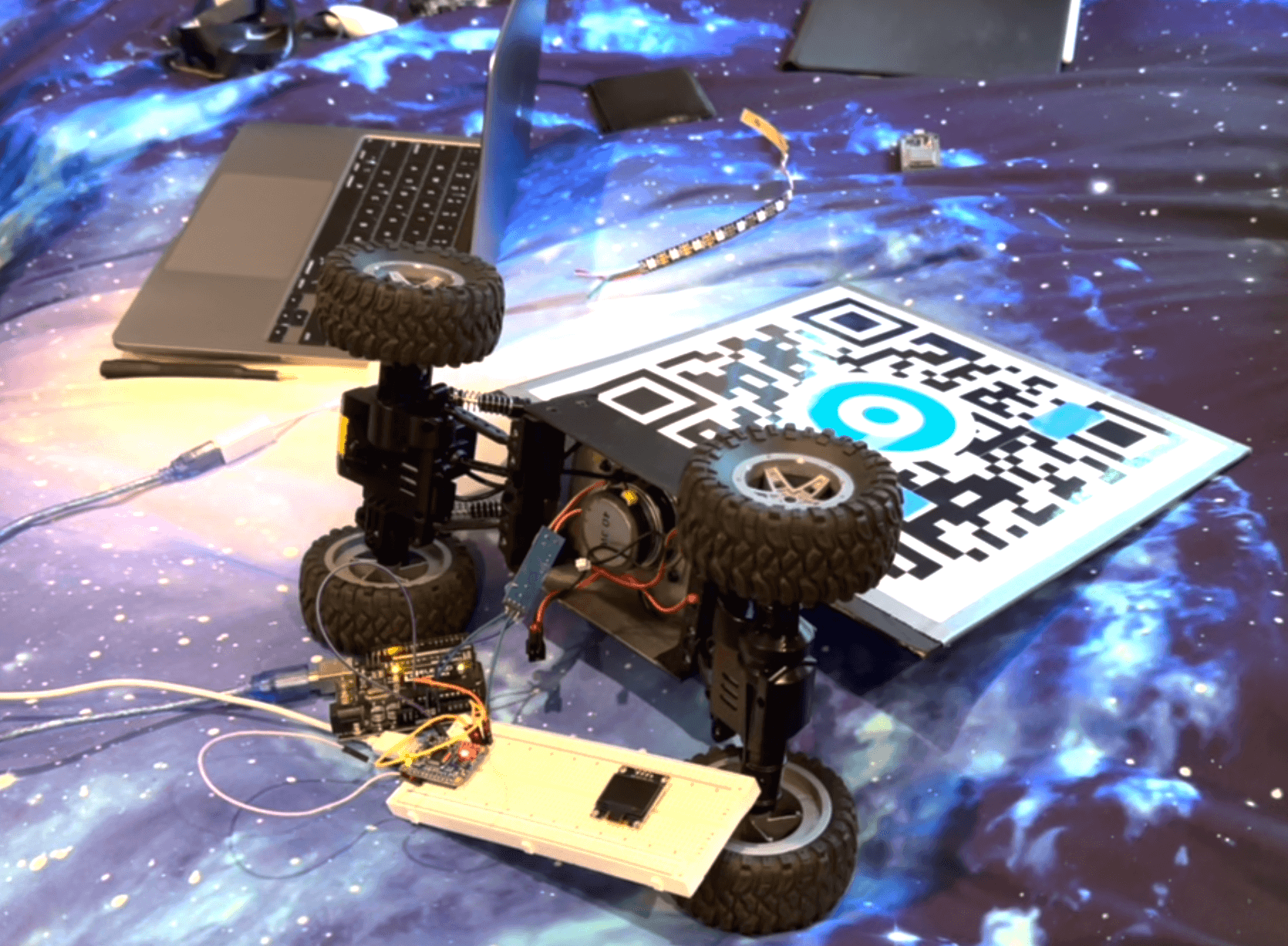

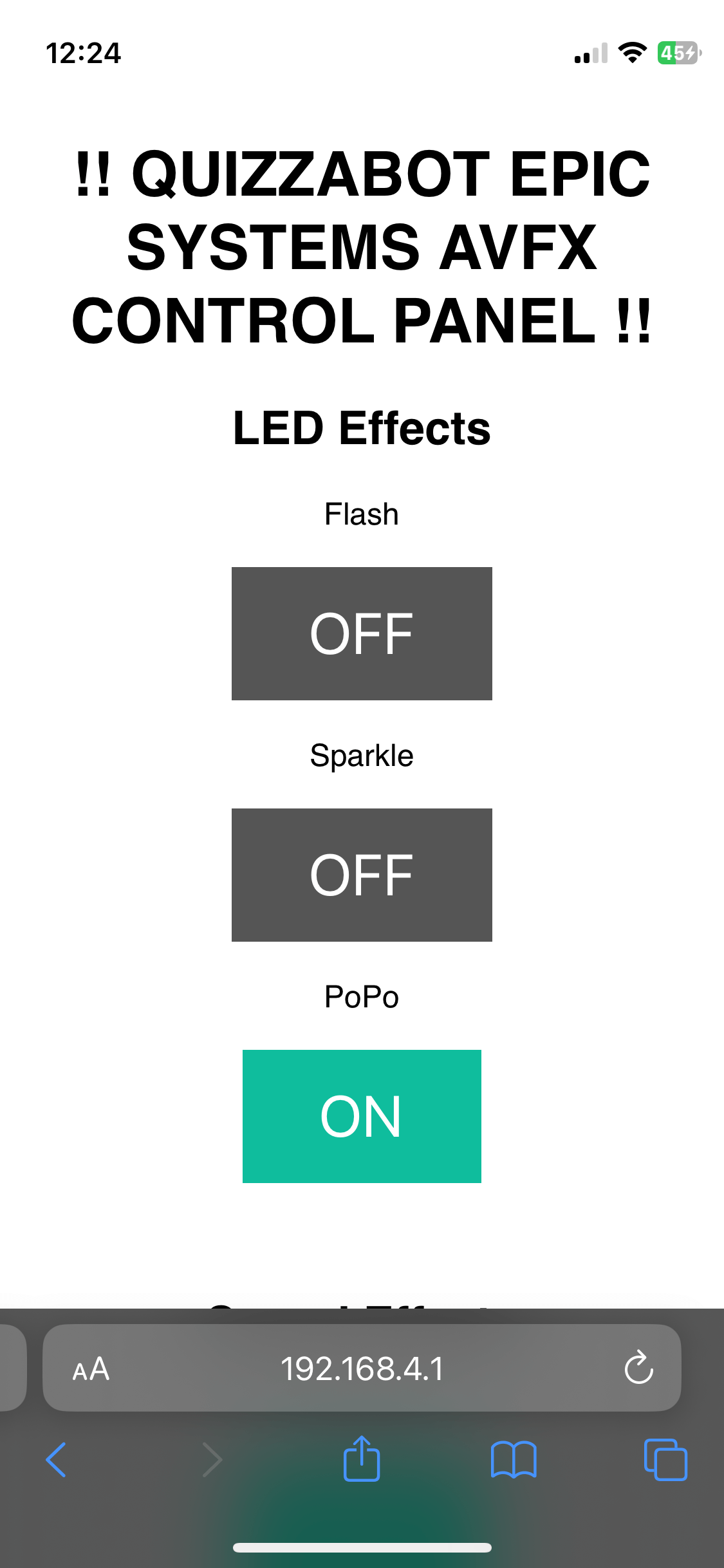

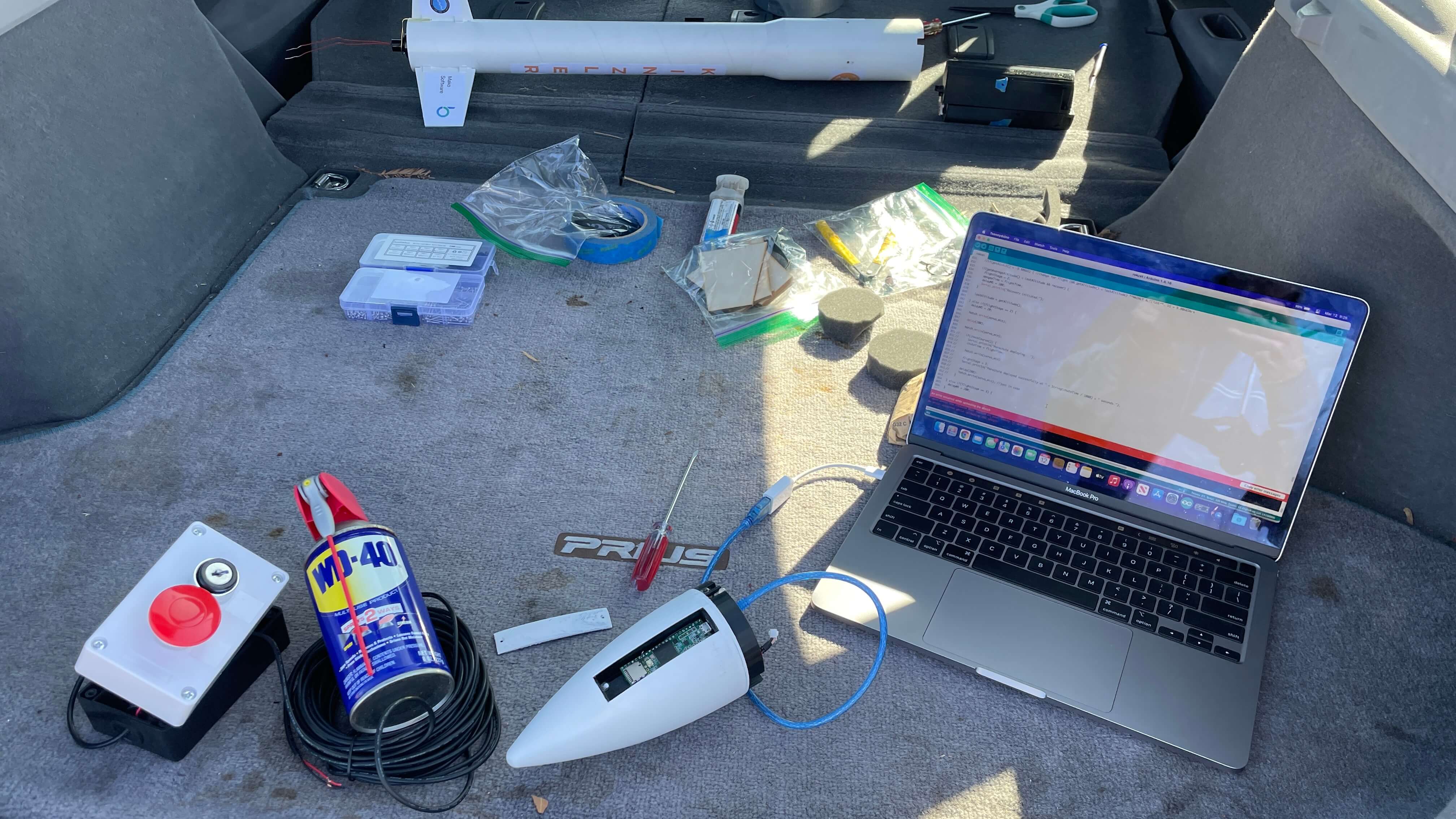

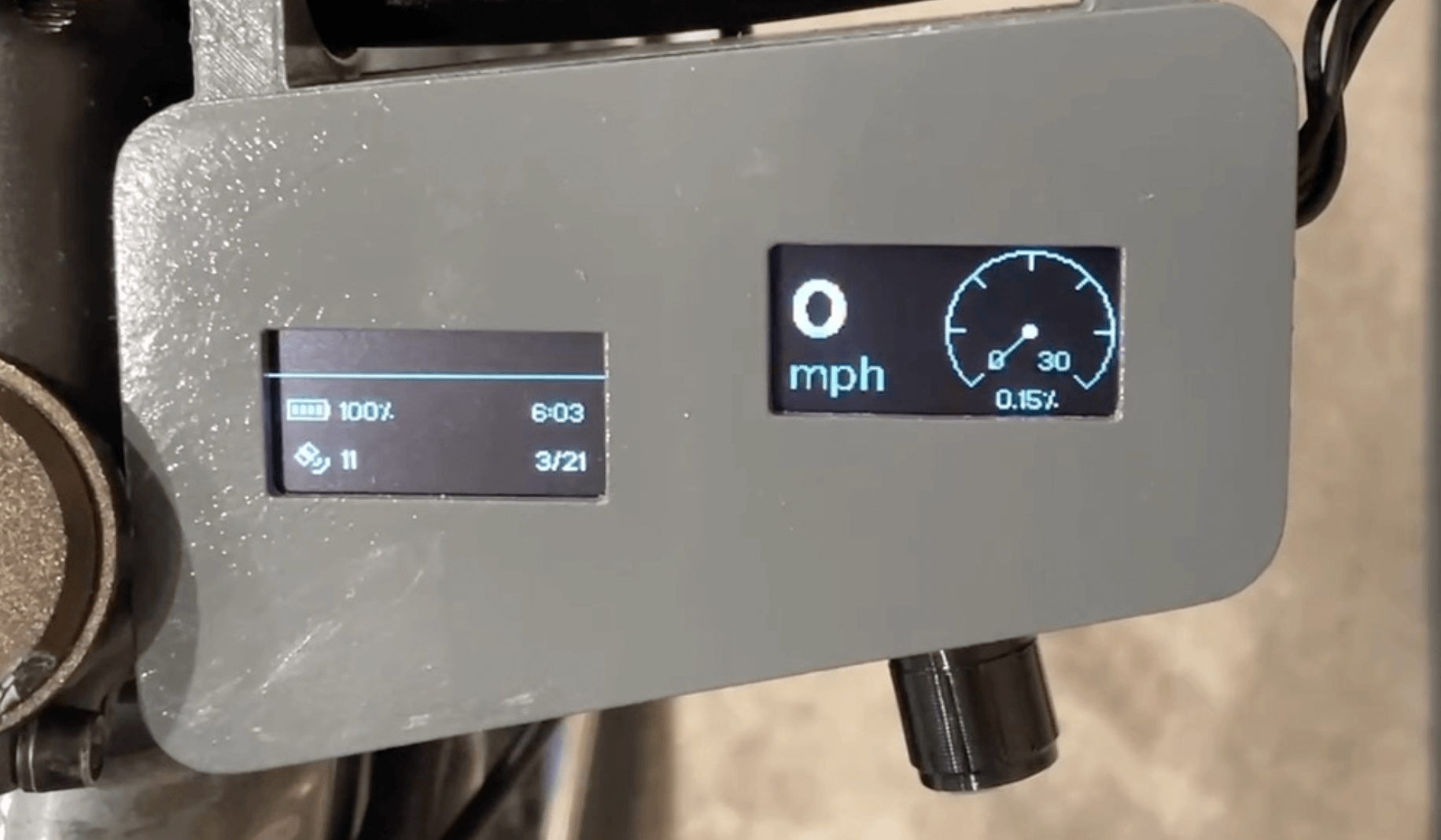

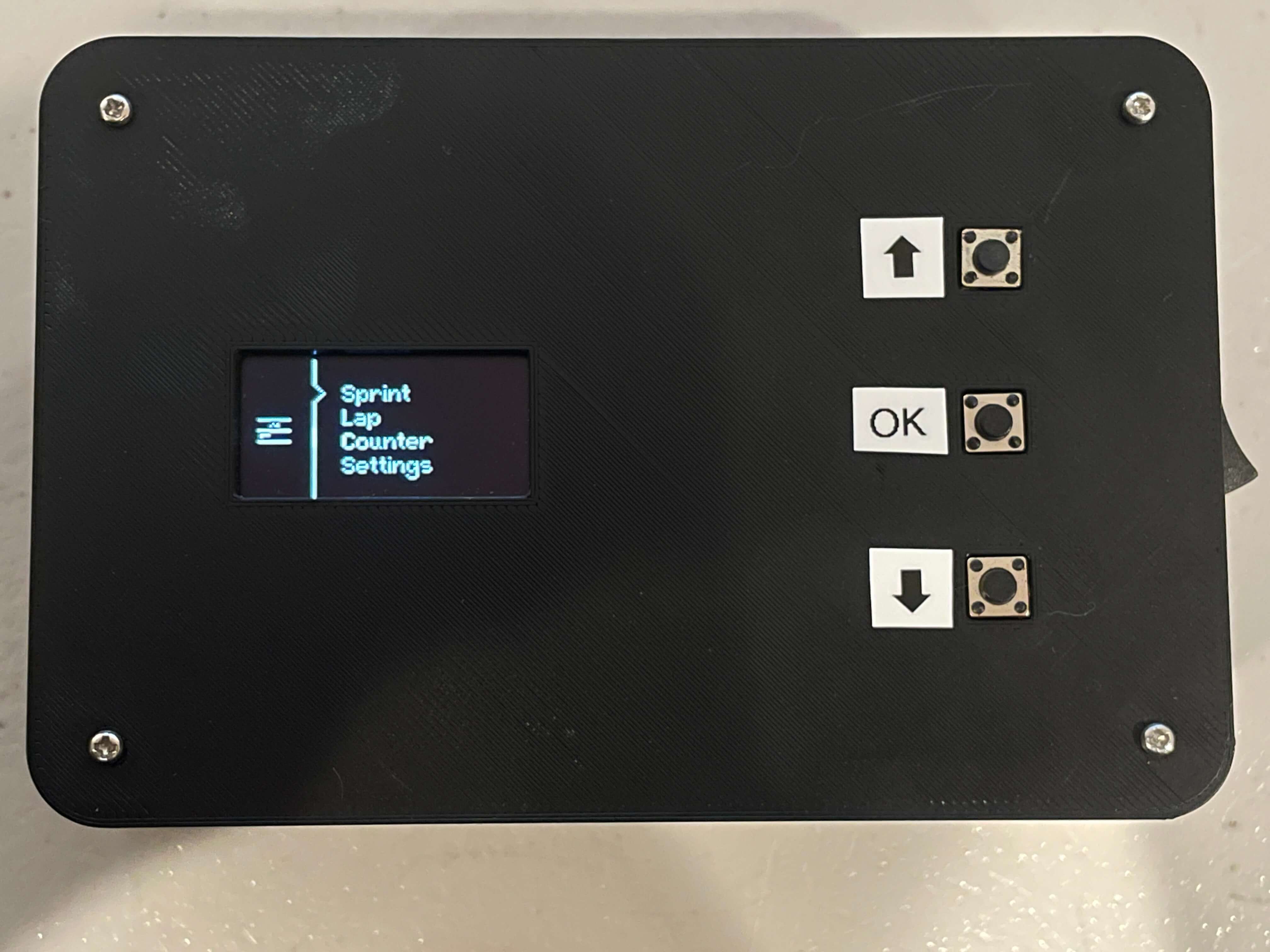

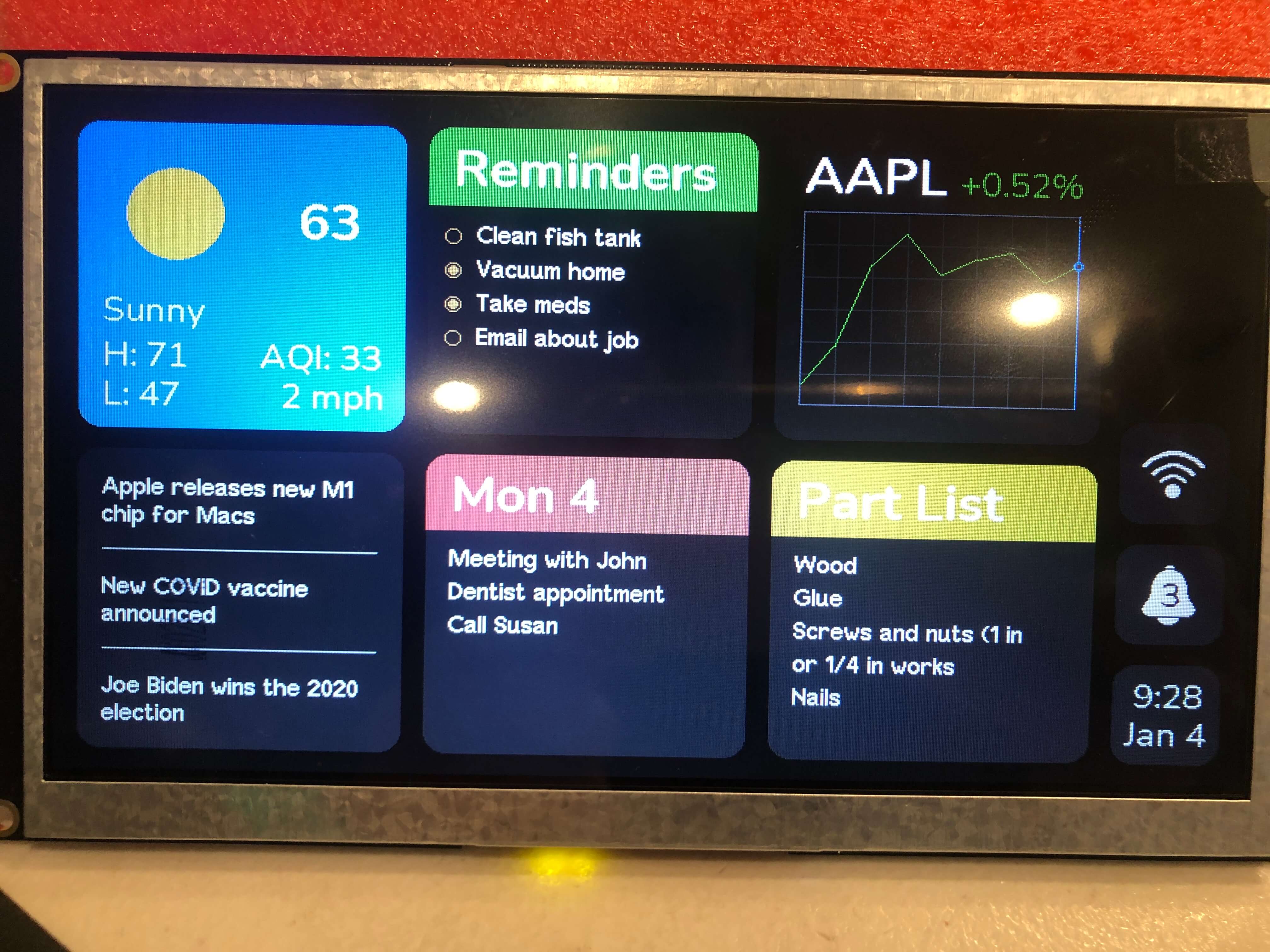

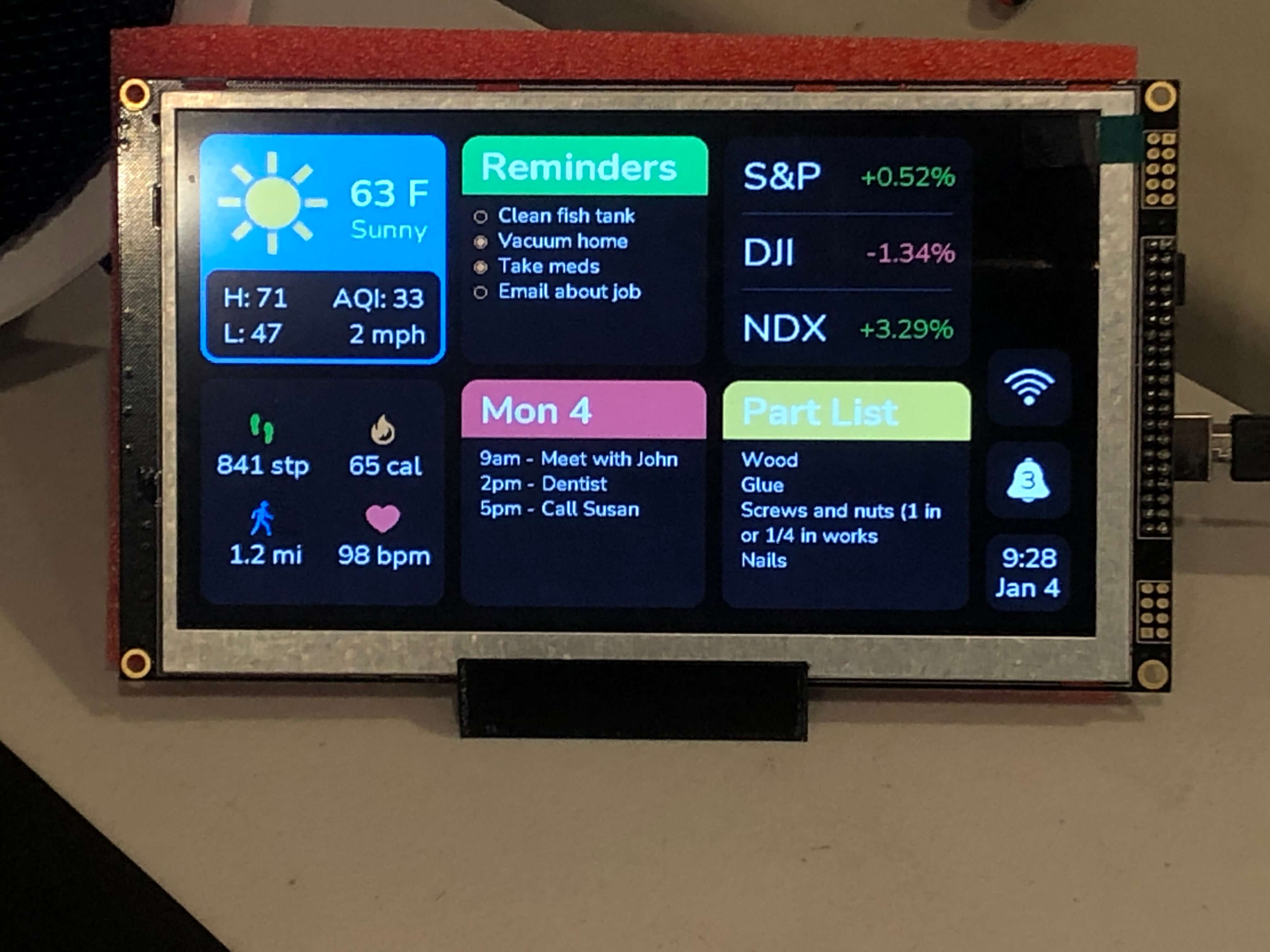

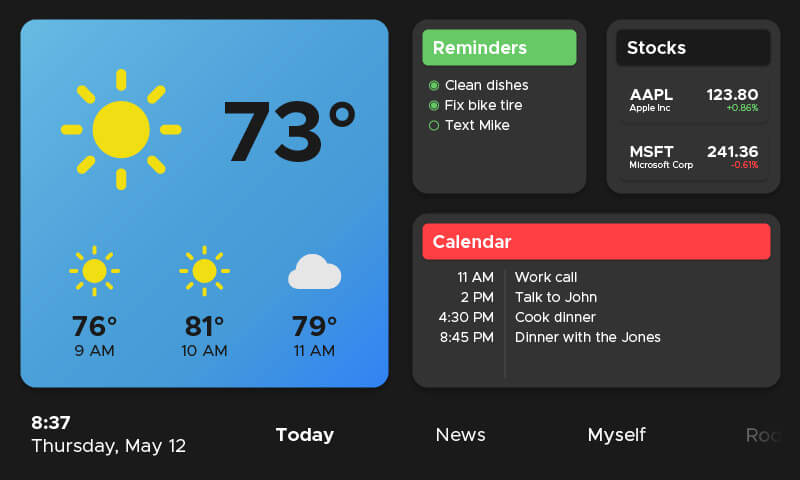

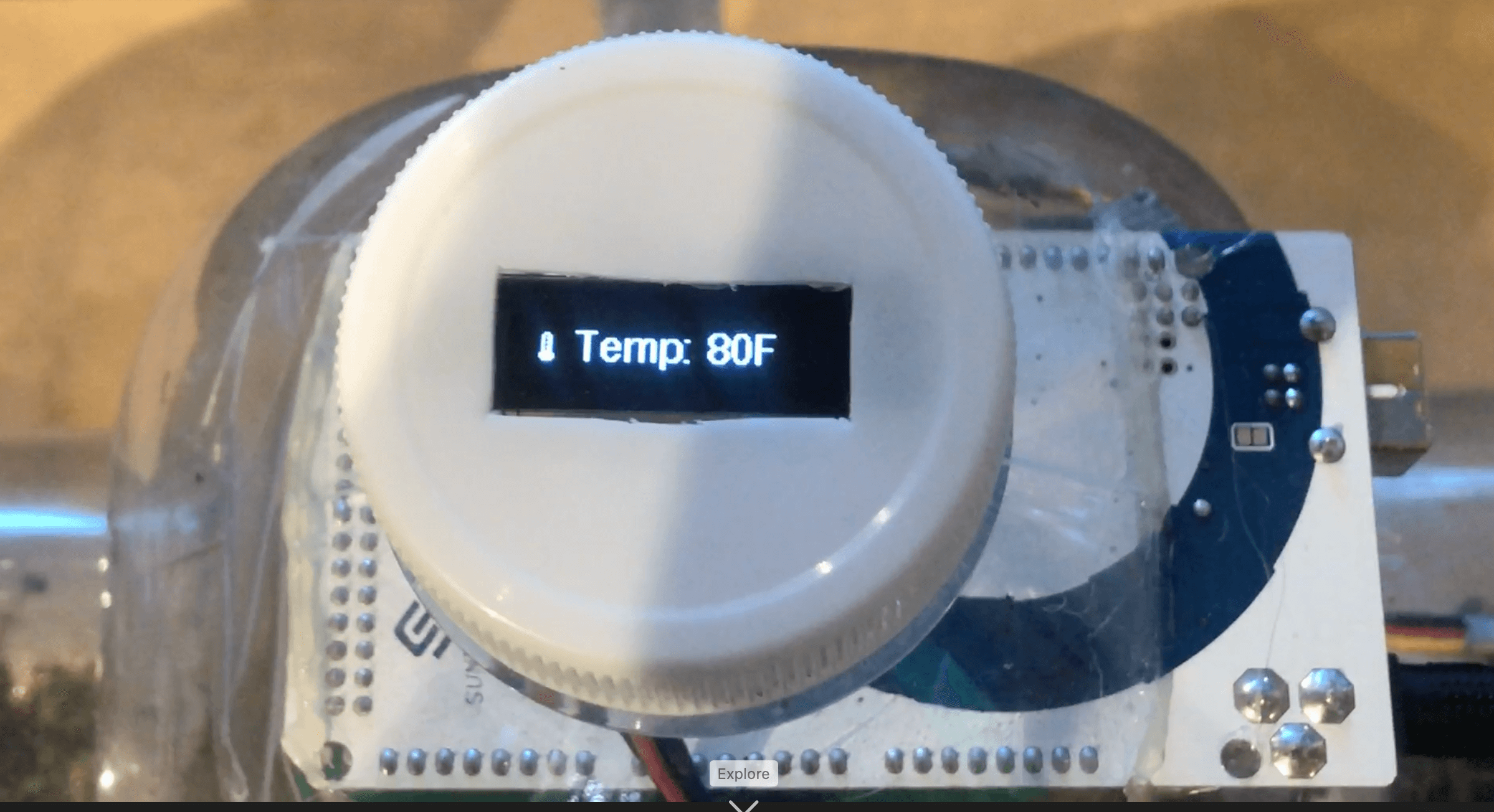

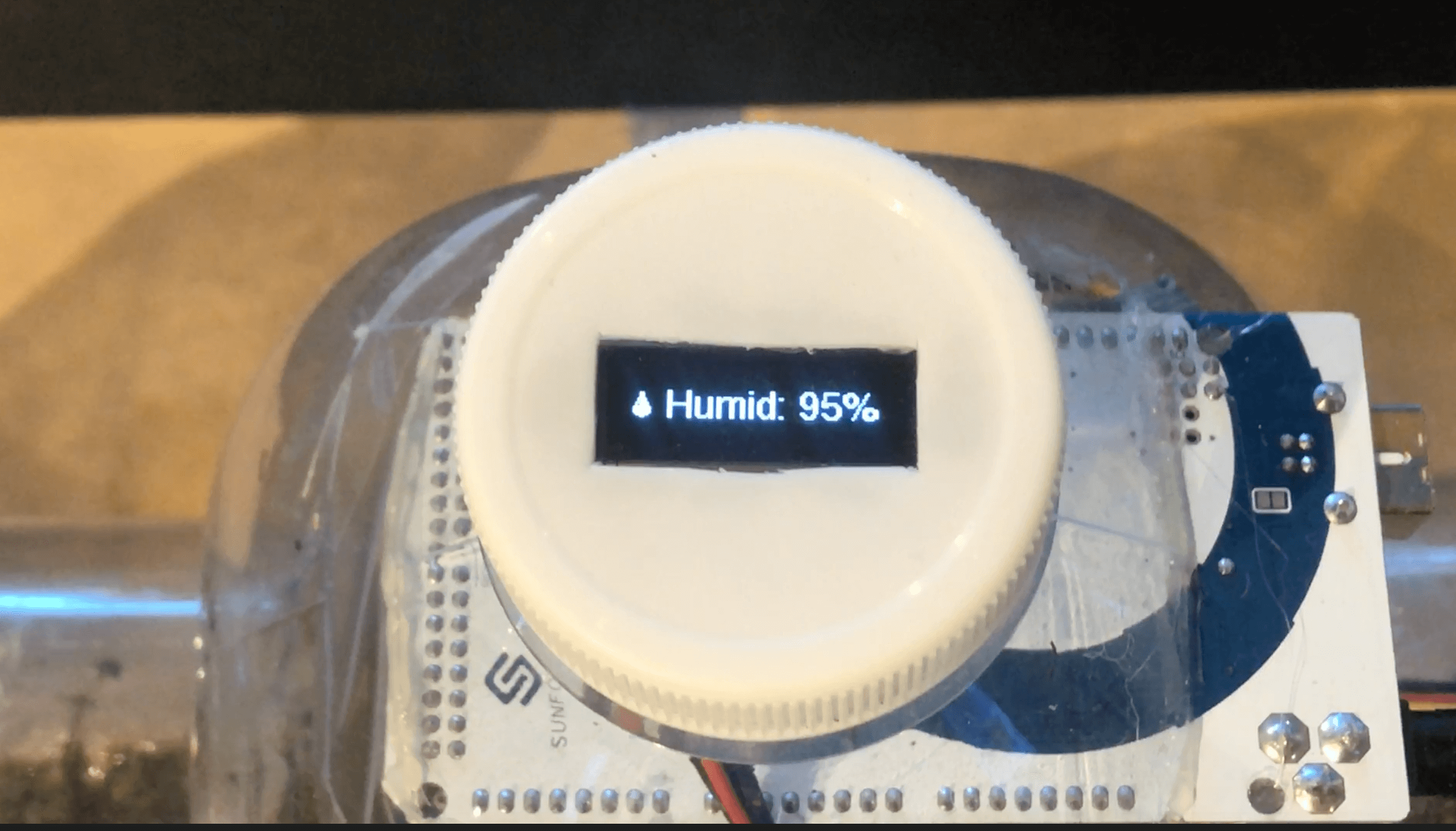

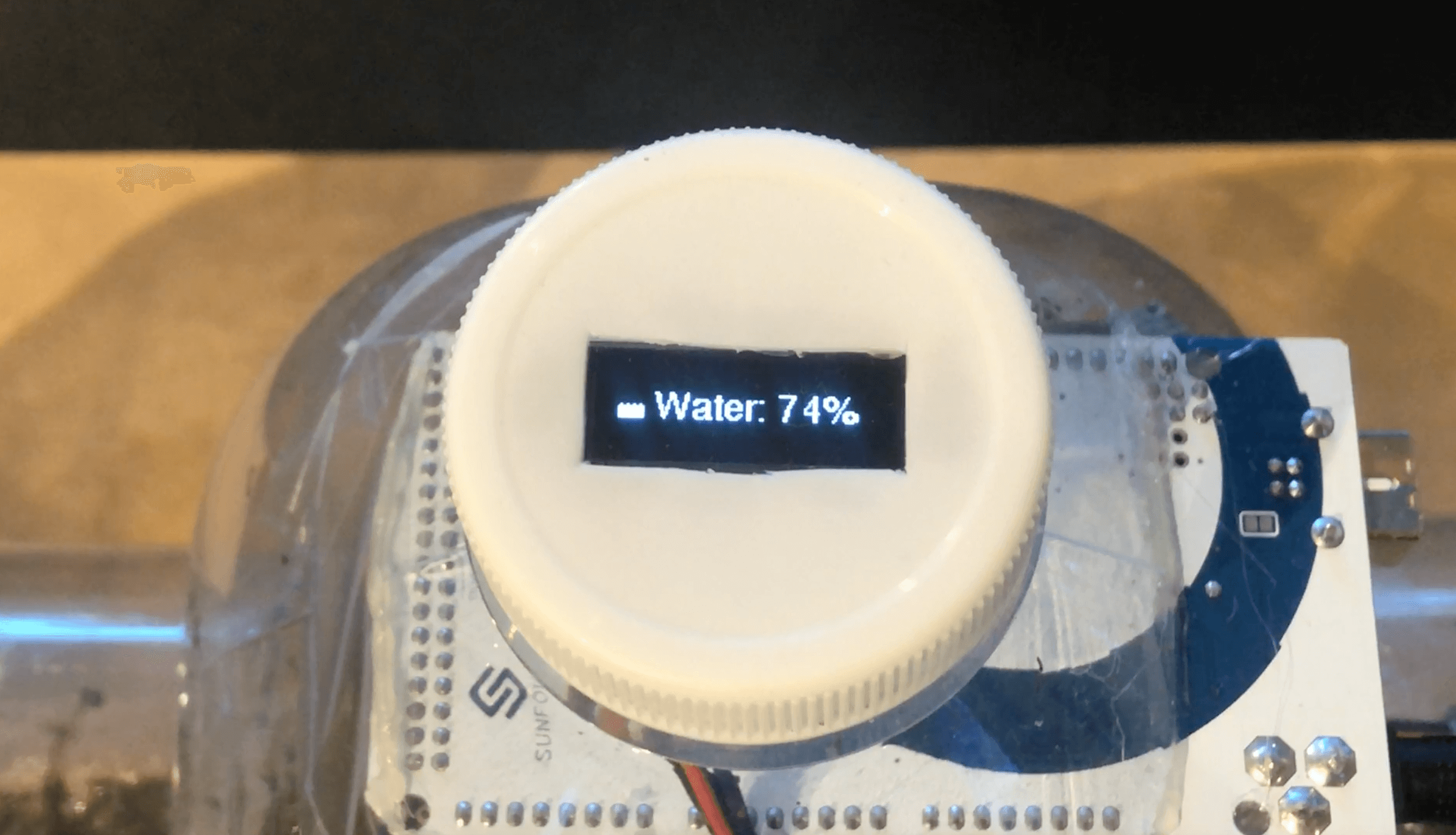

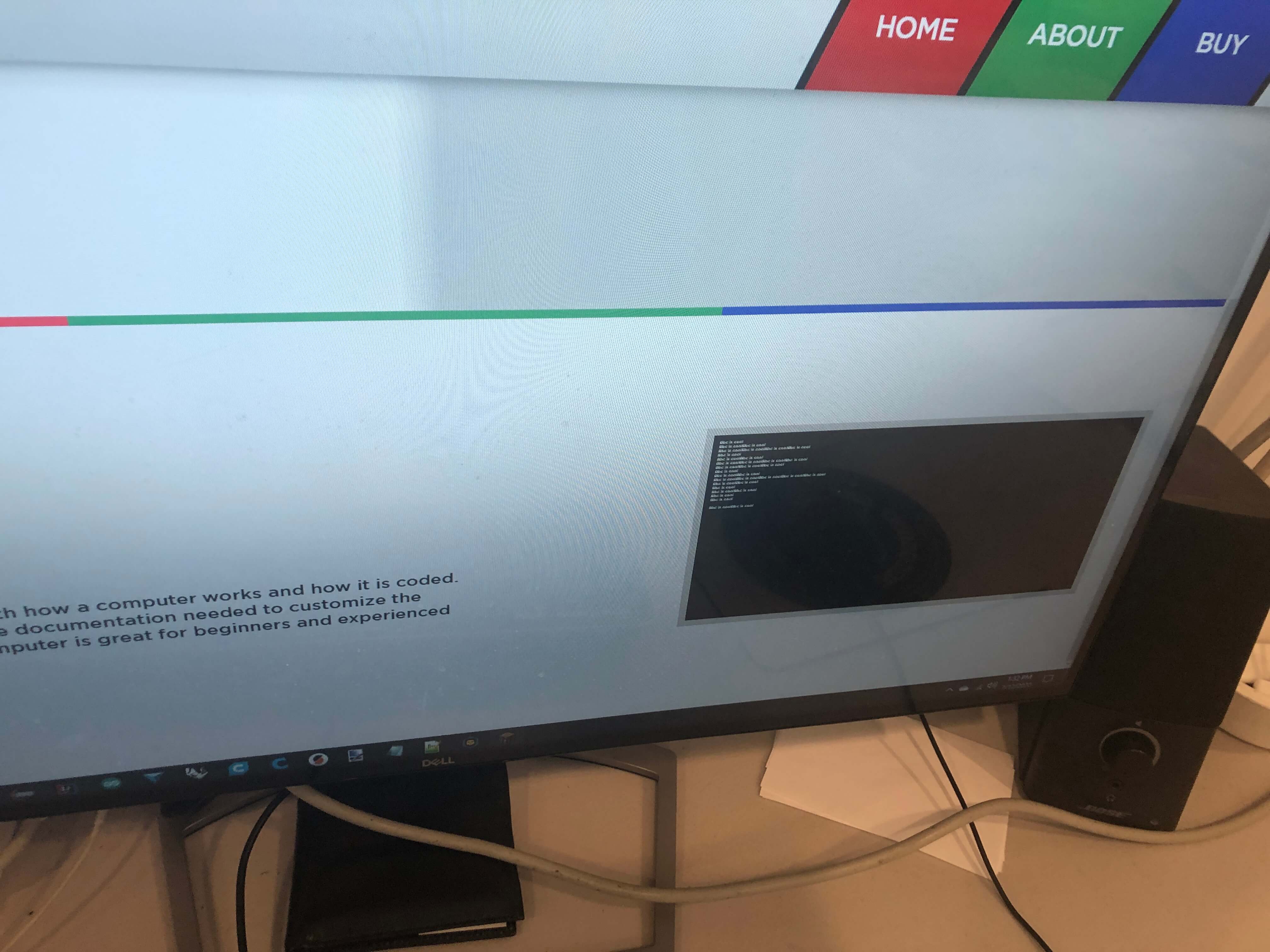

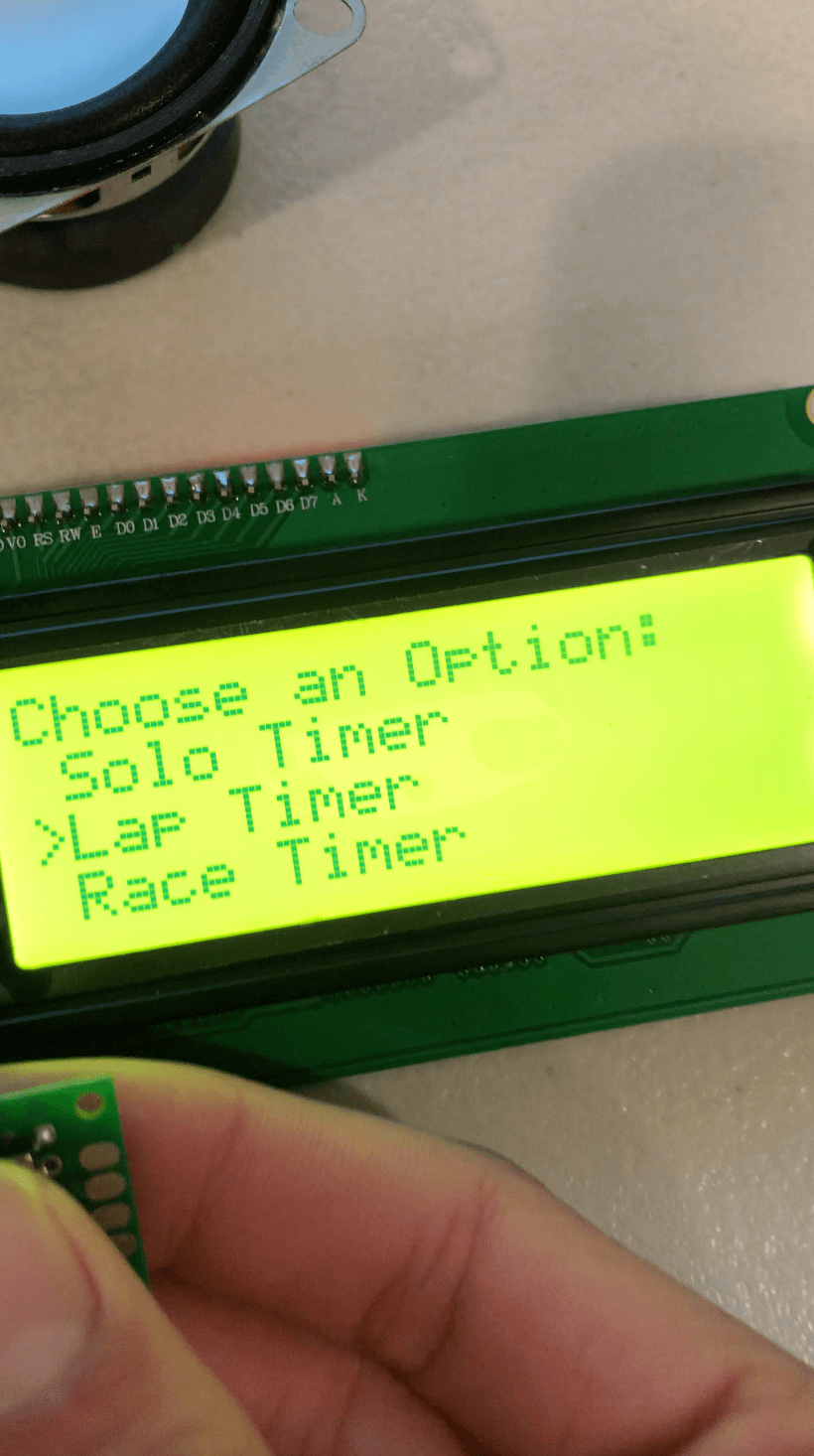

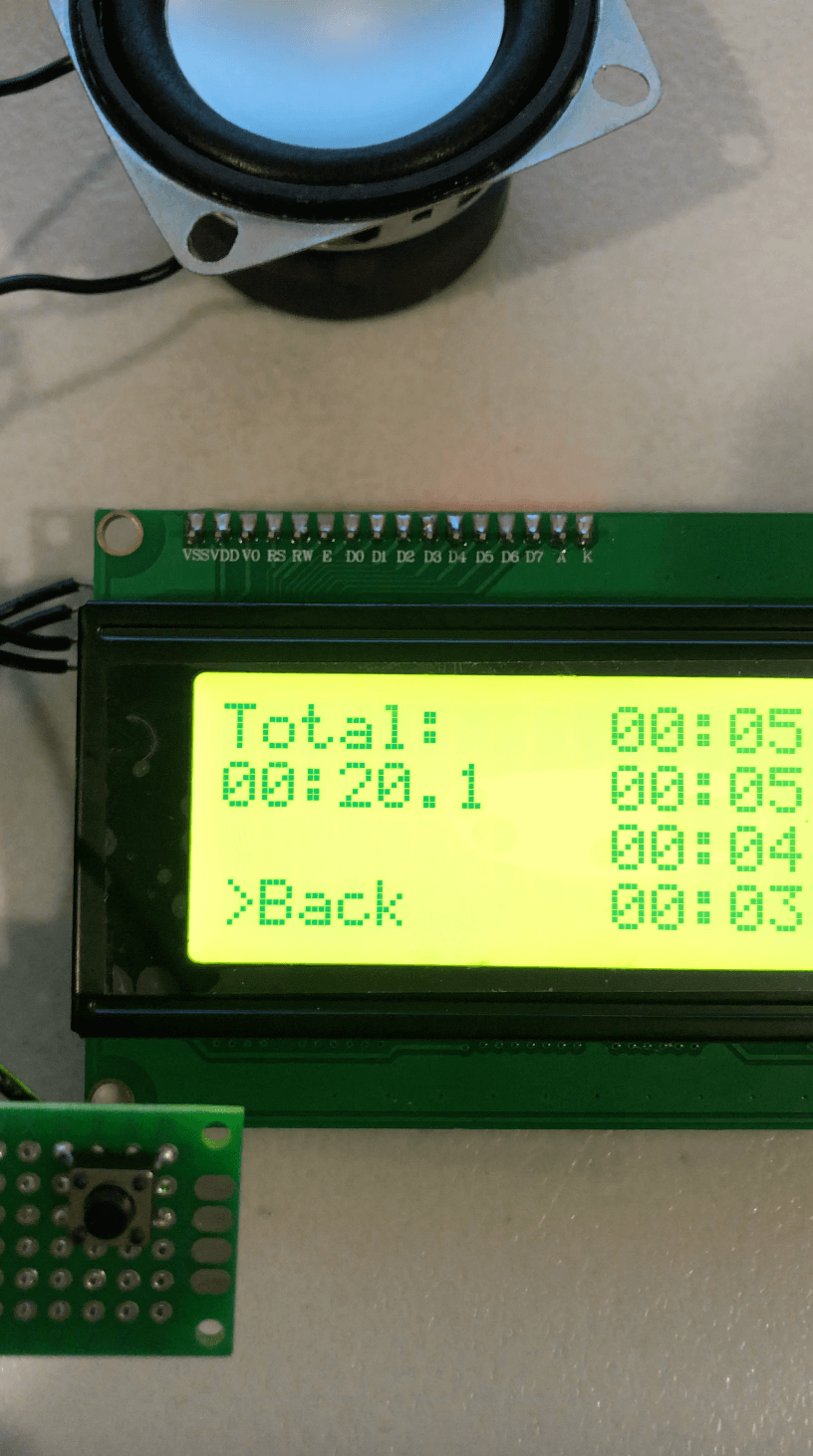

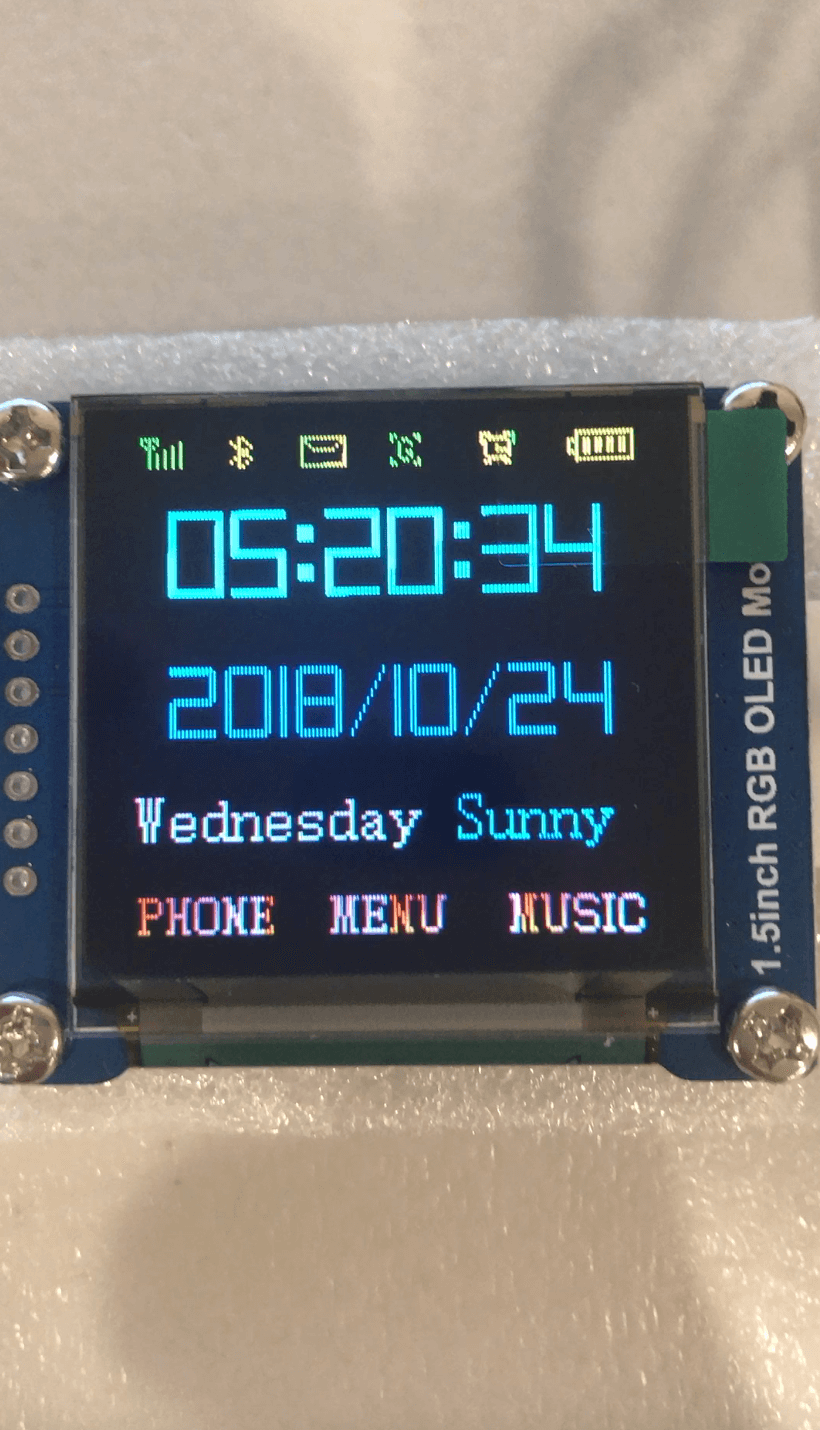

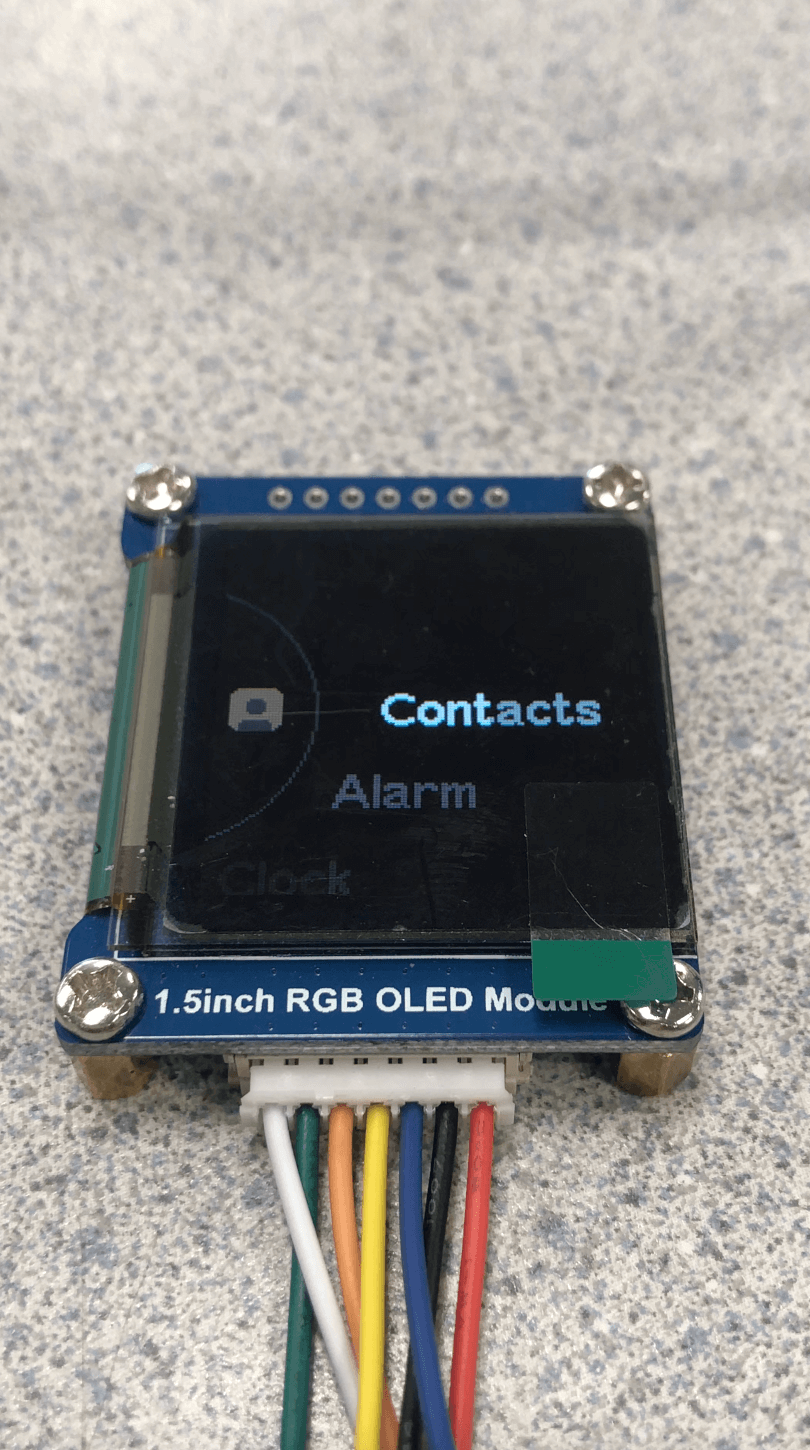

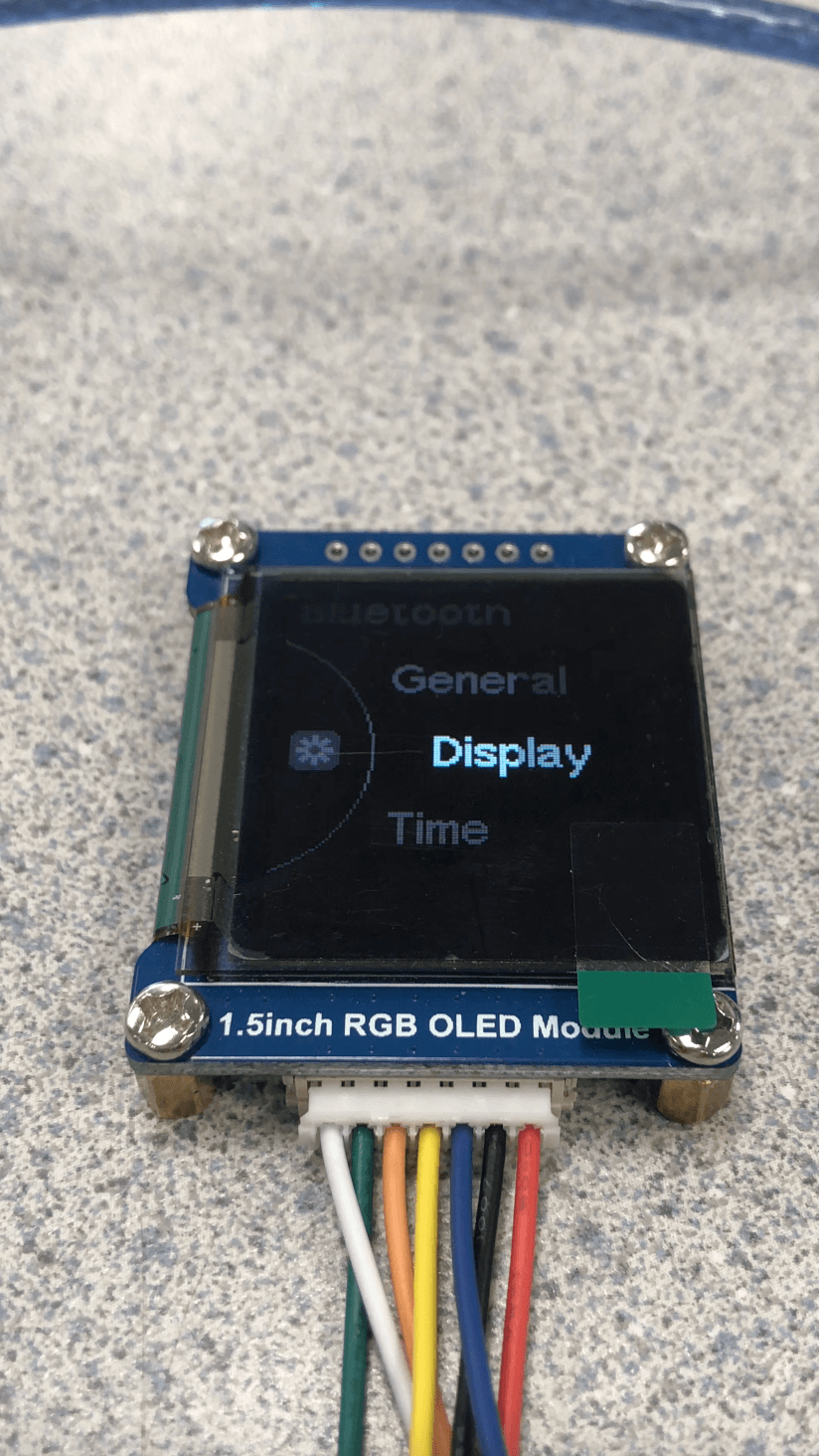

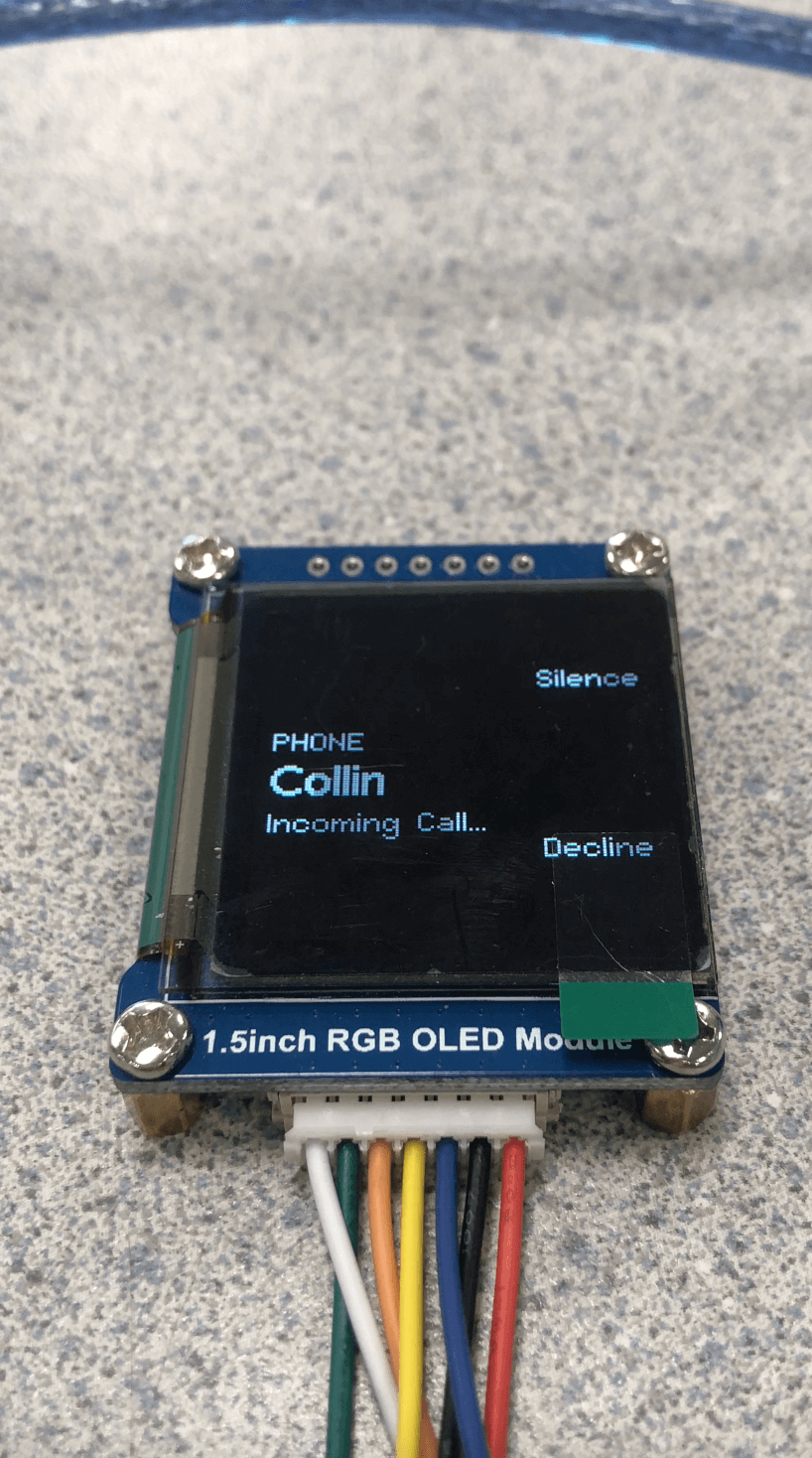

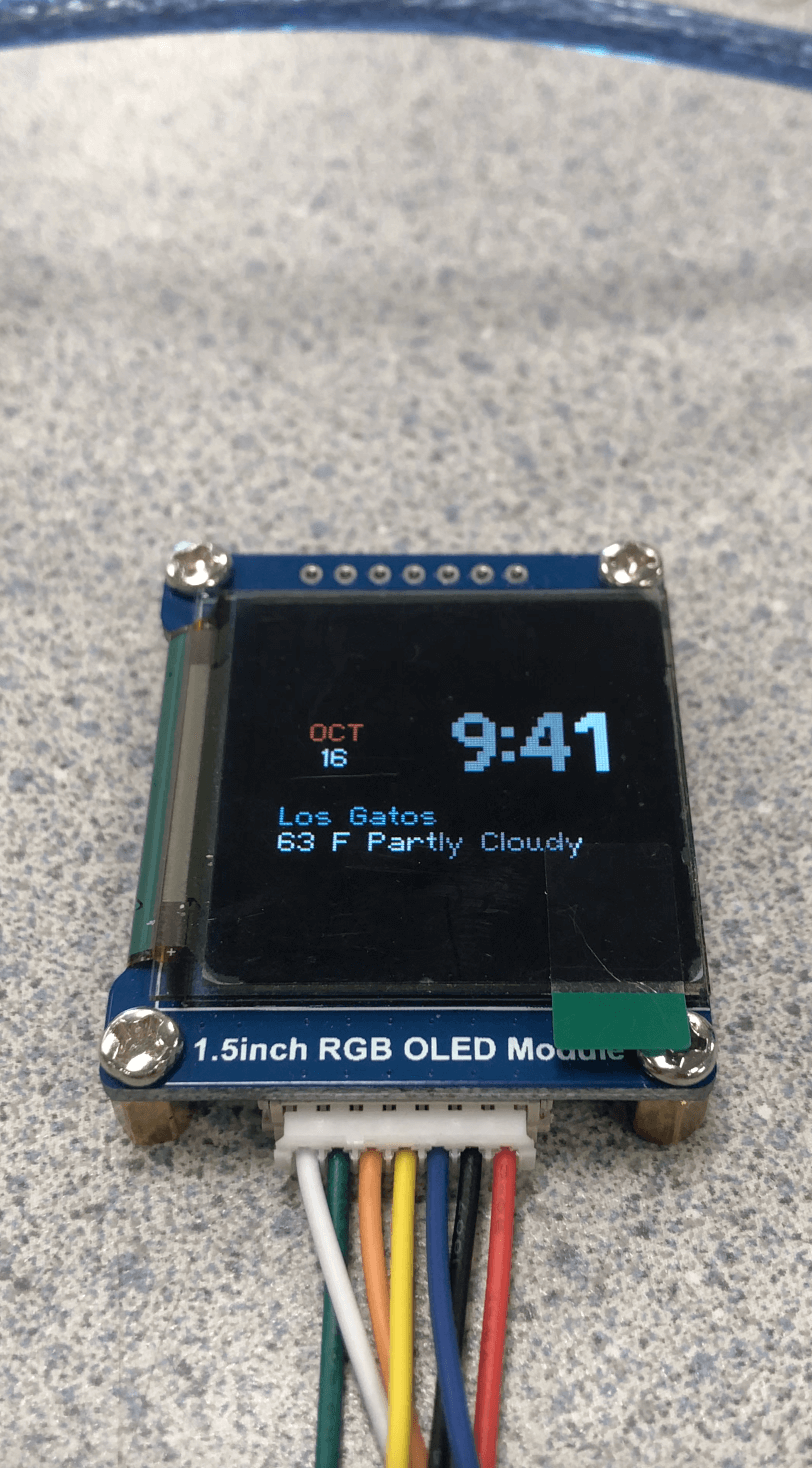

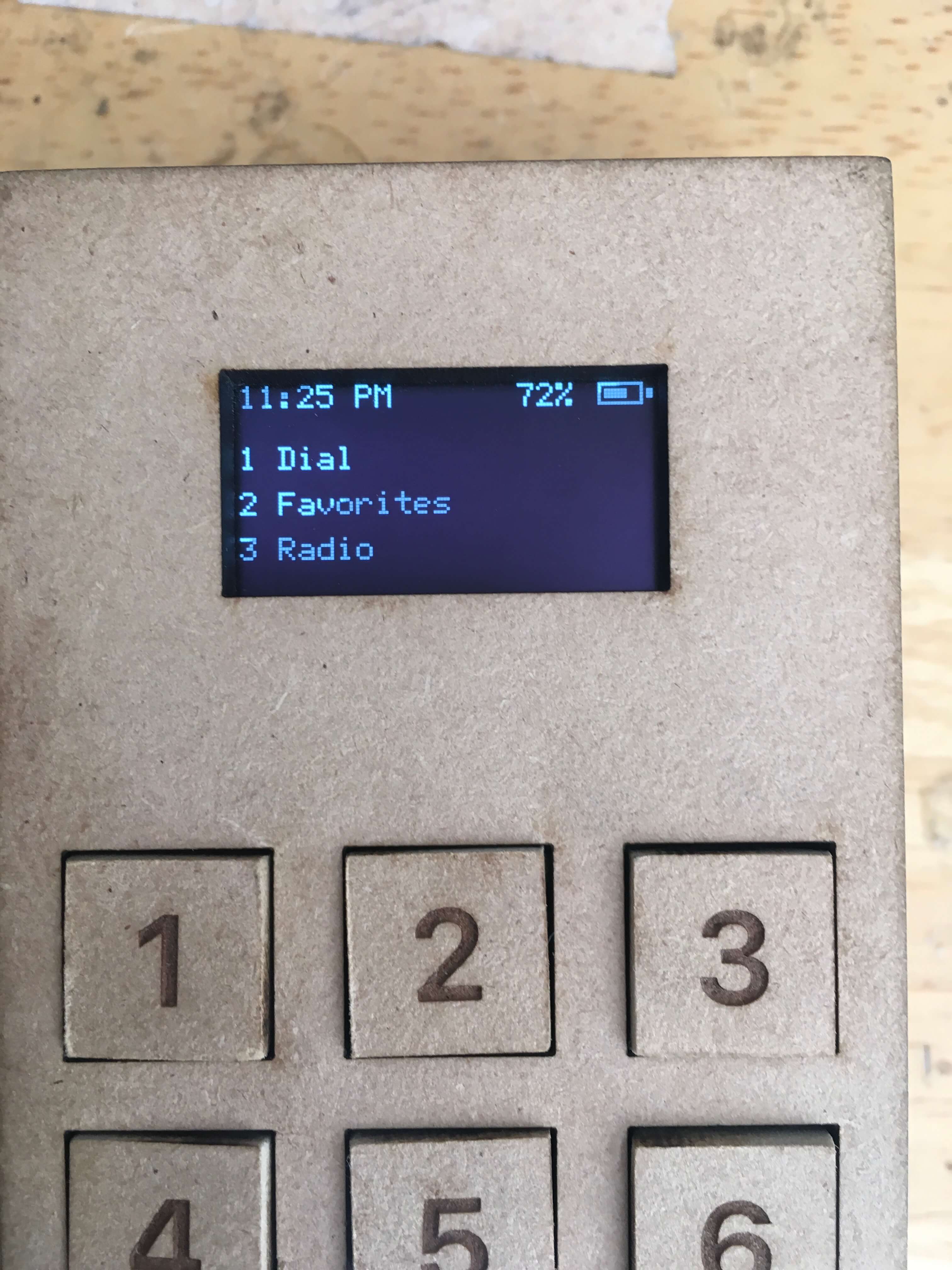

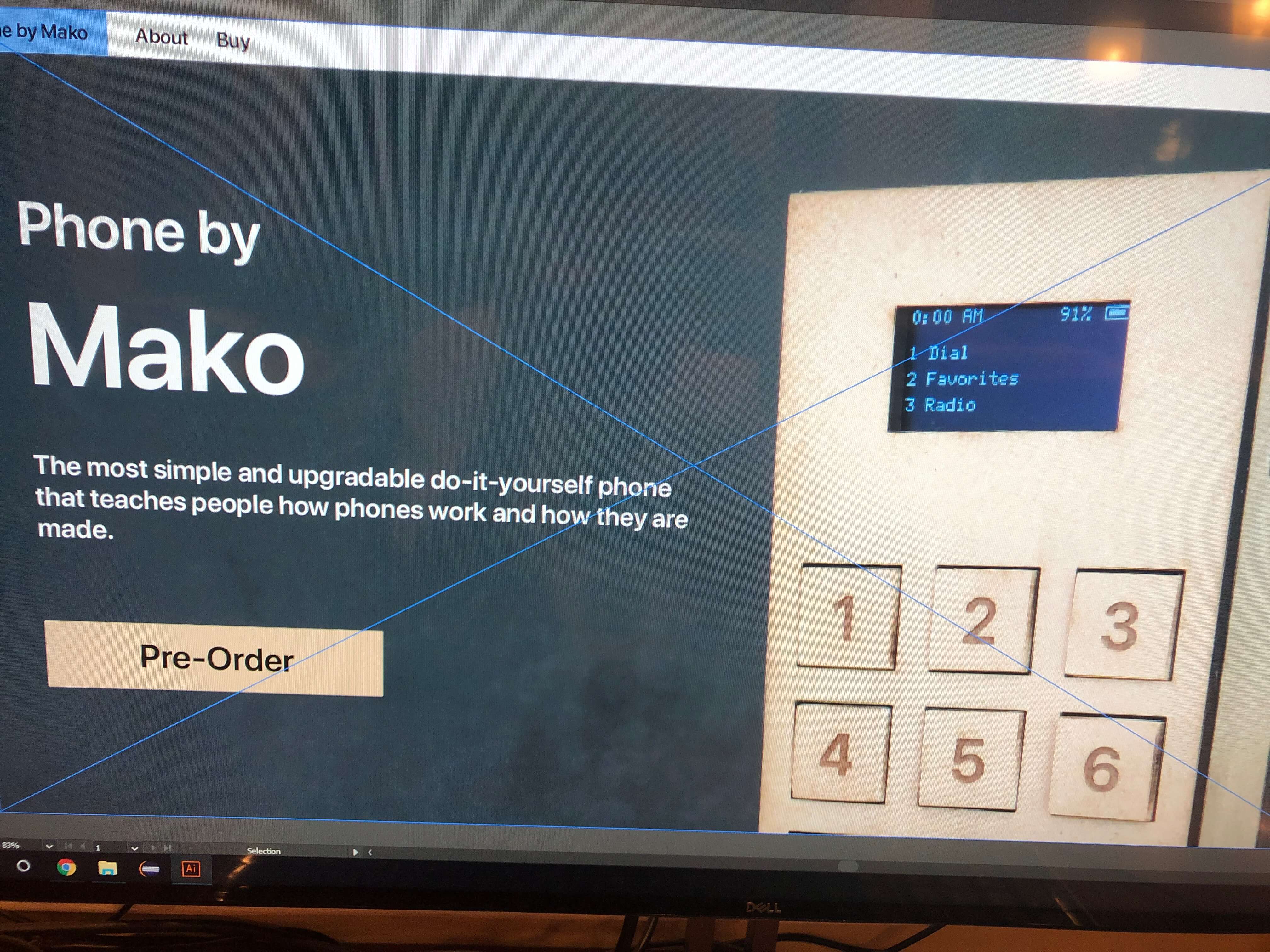

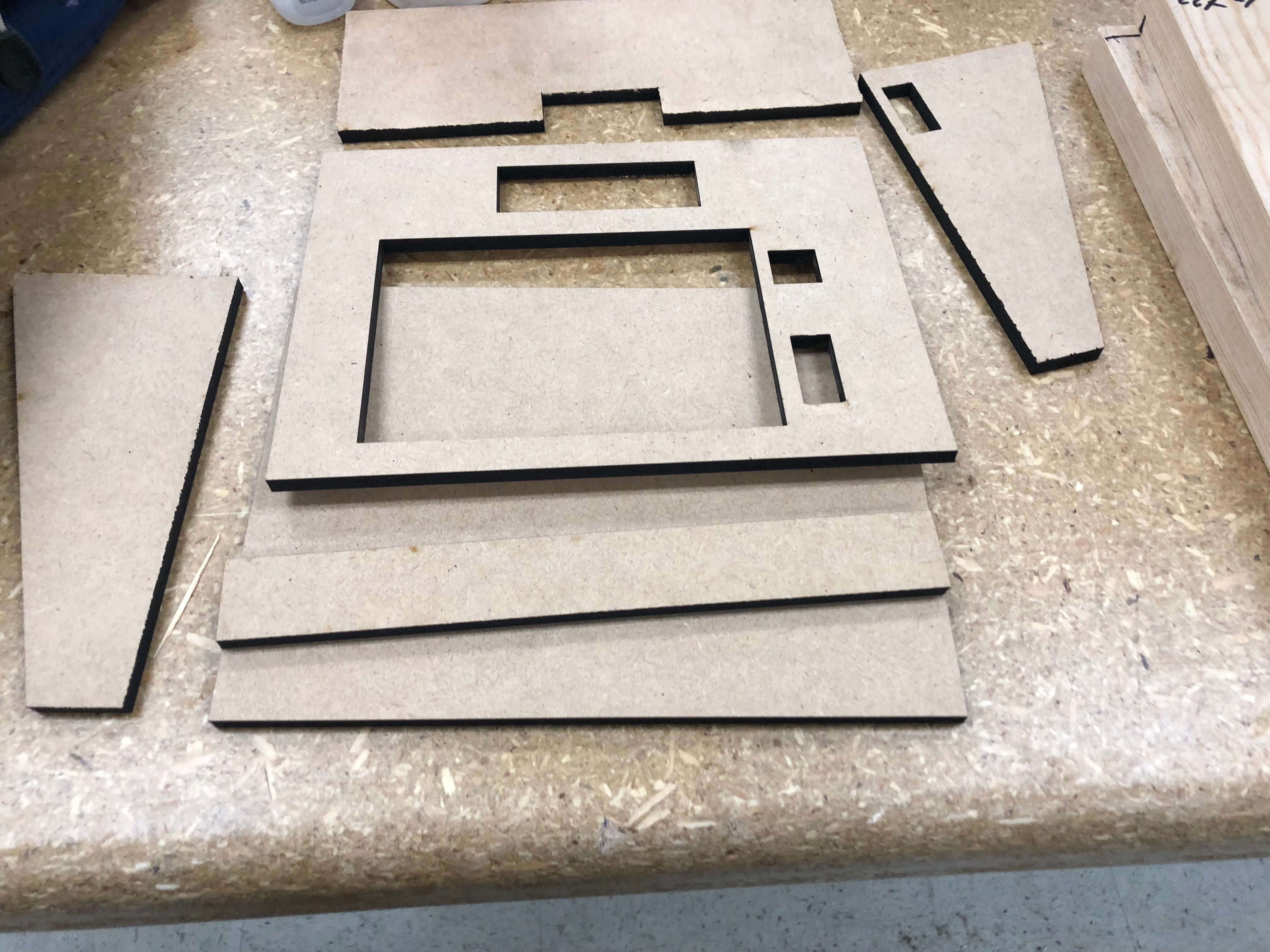

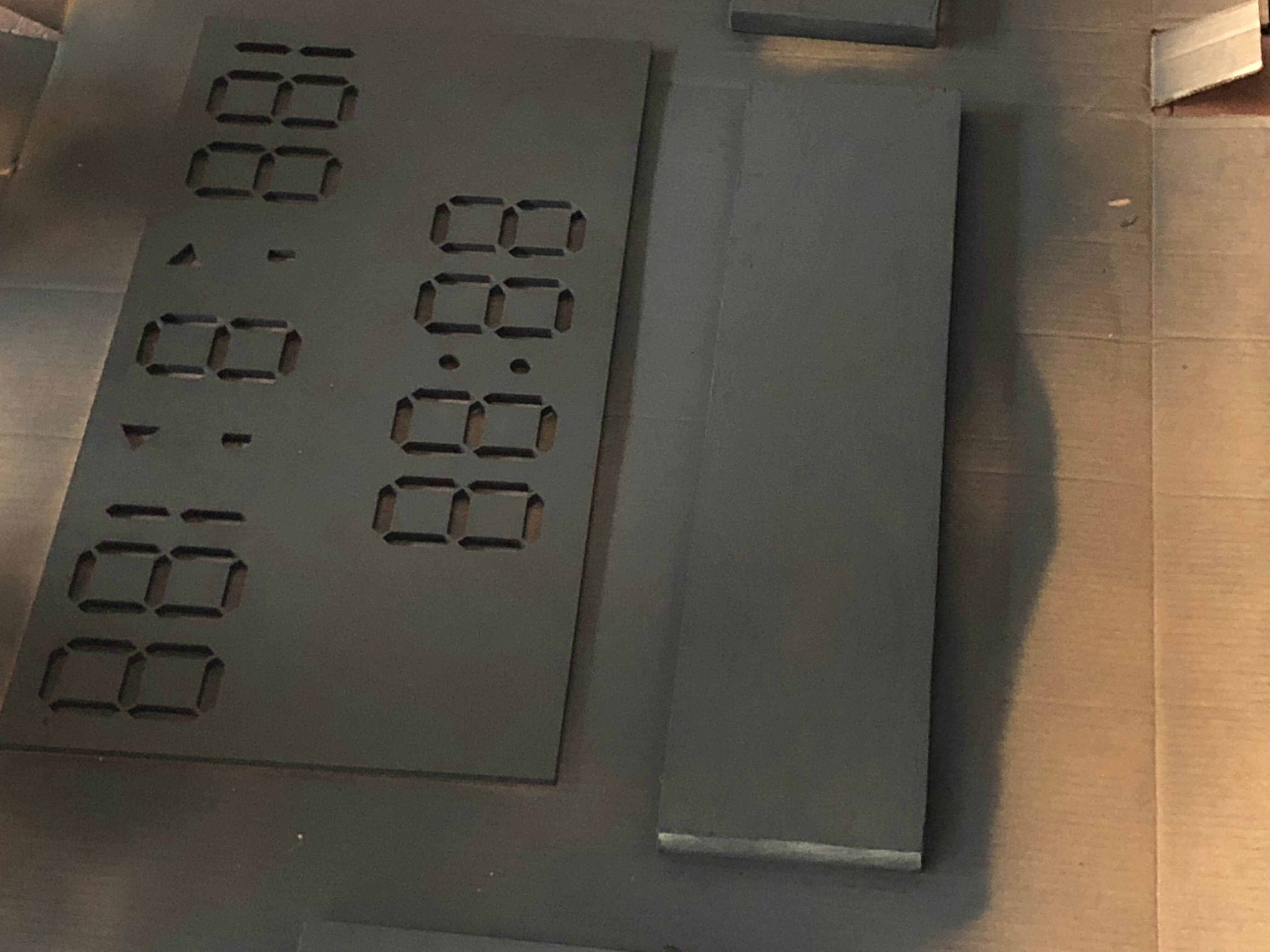

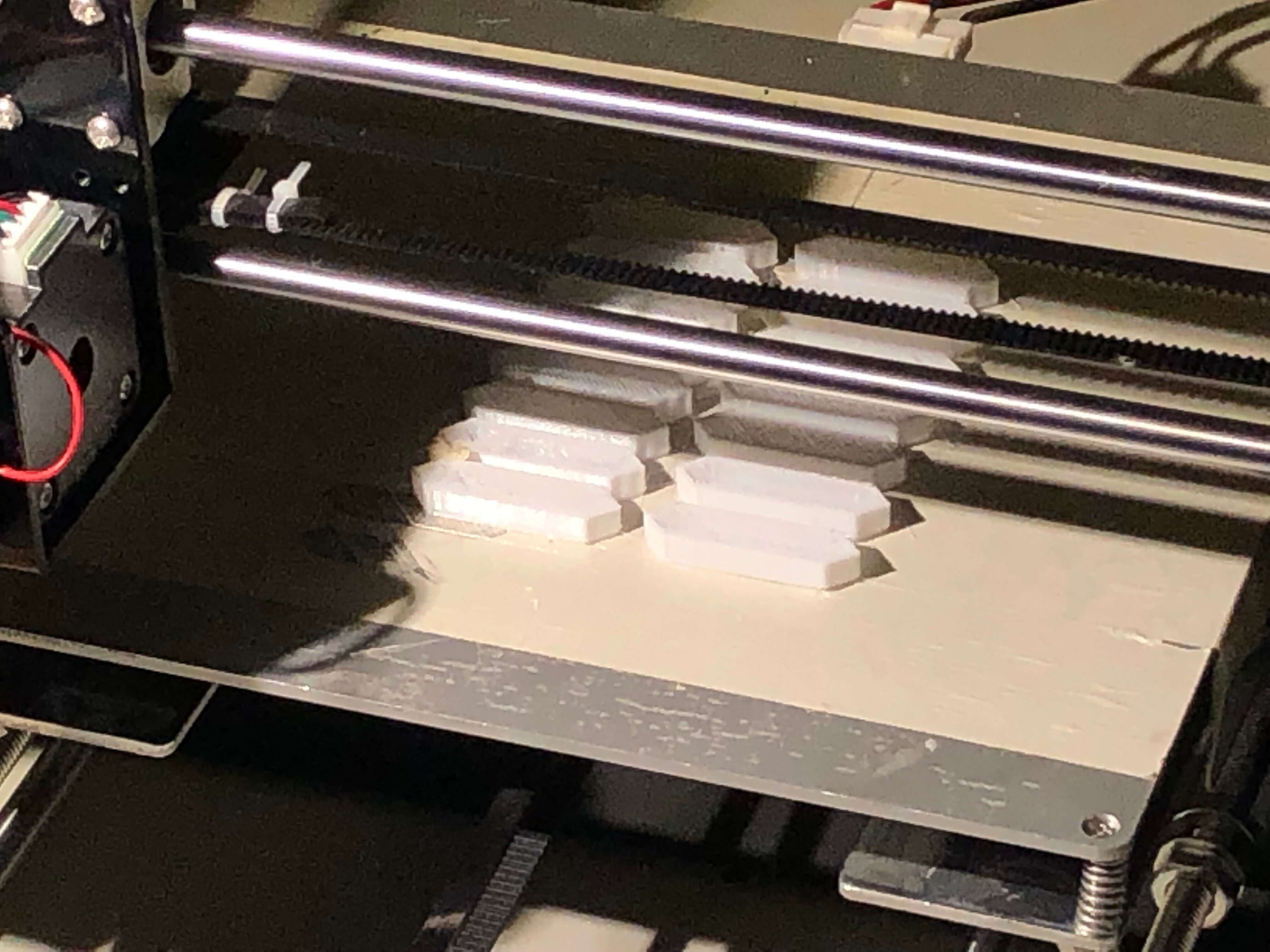

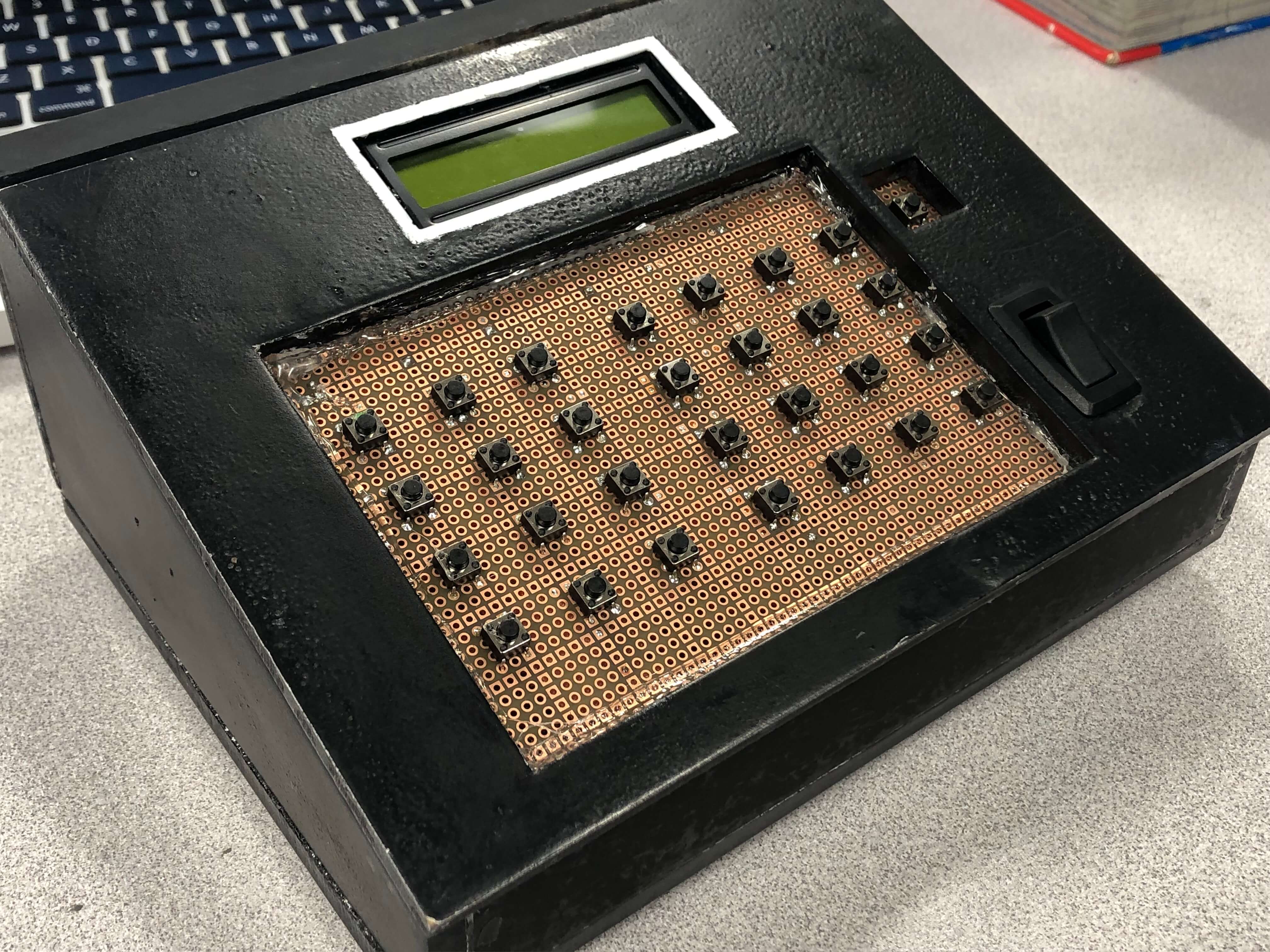

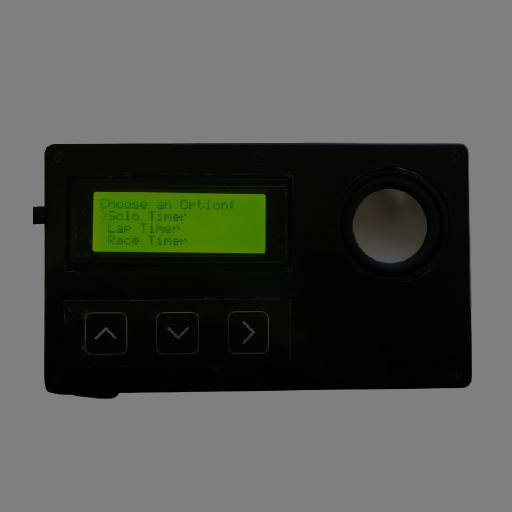

This project was designed with simplicity at the forefront, although I didn’t want to sacrifice any usability. Therefore, Lumle displays the time, weather, alarms, and the day’s events streamed from Google Calendar, all on a 2.5 inch monochrome OLED display.

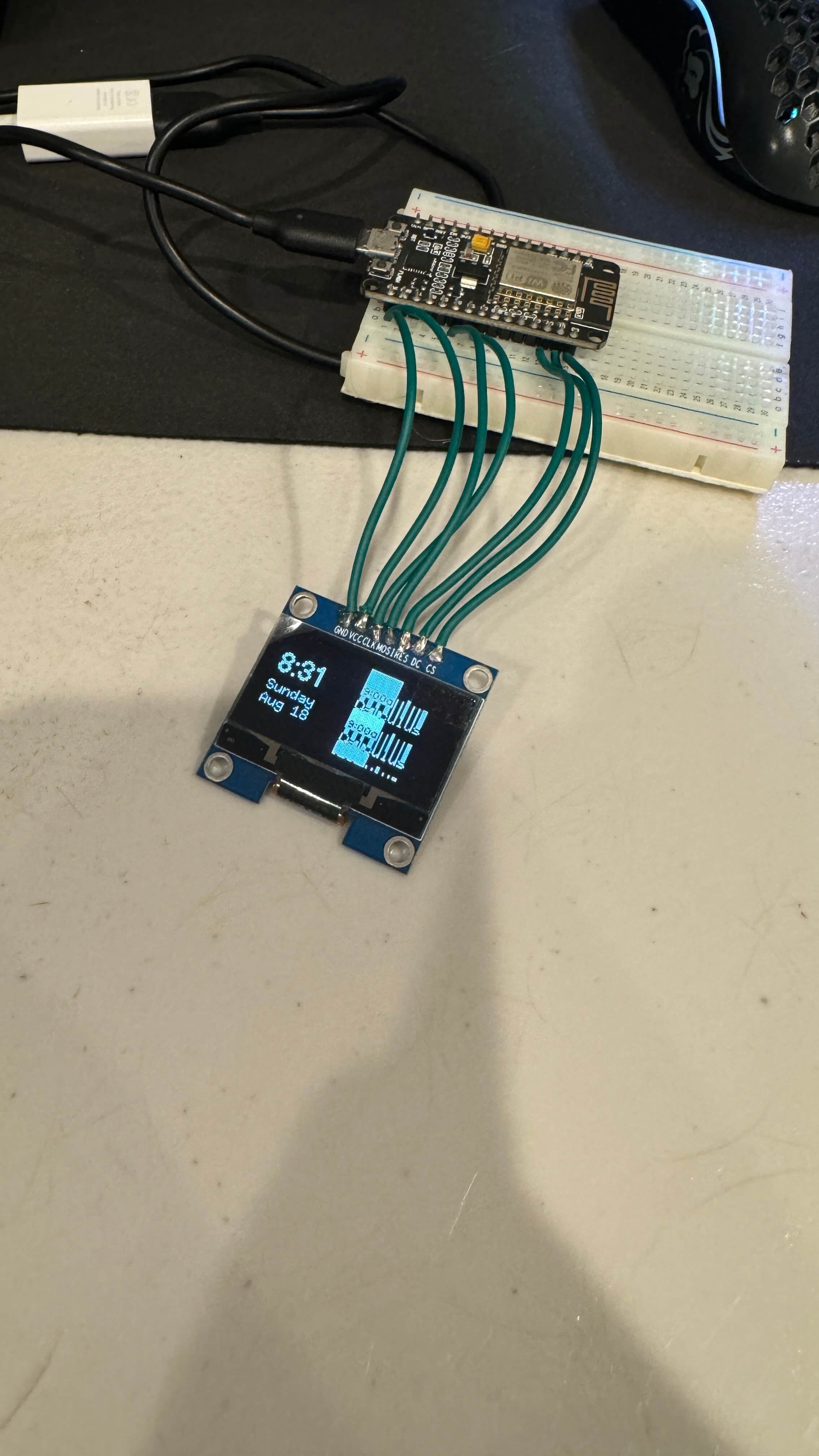

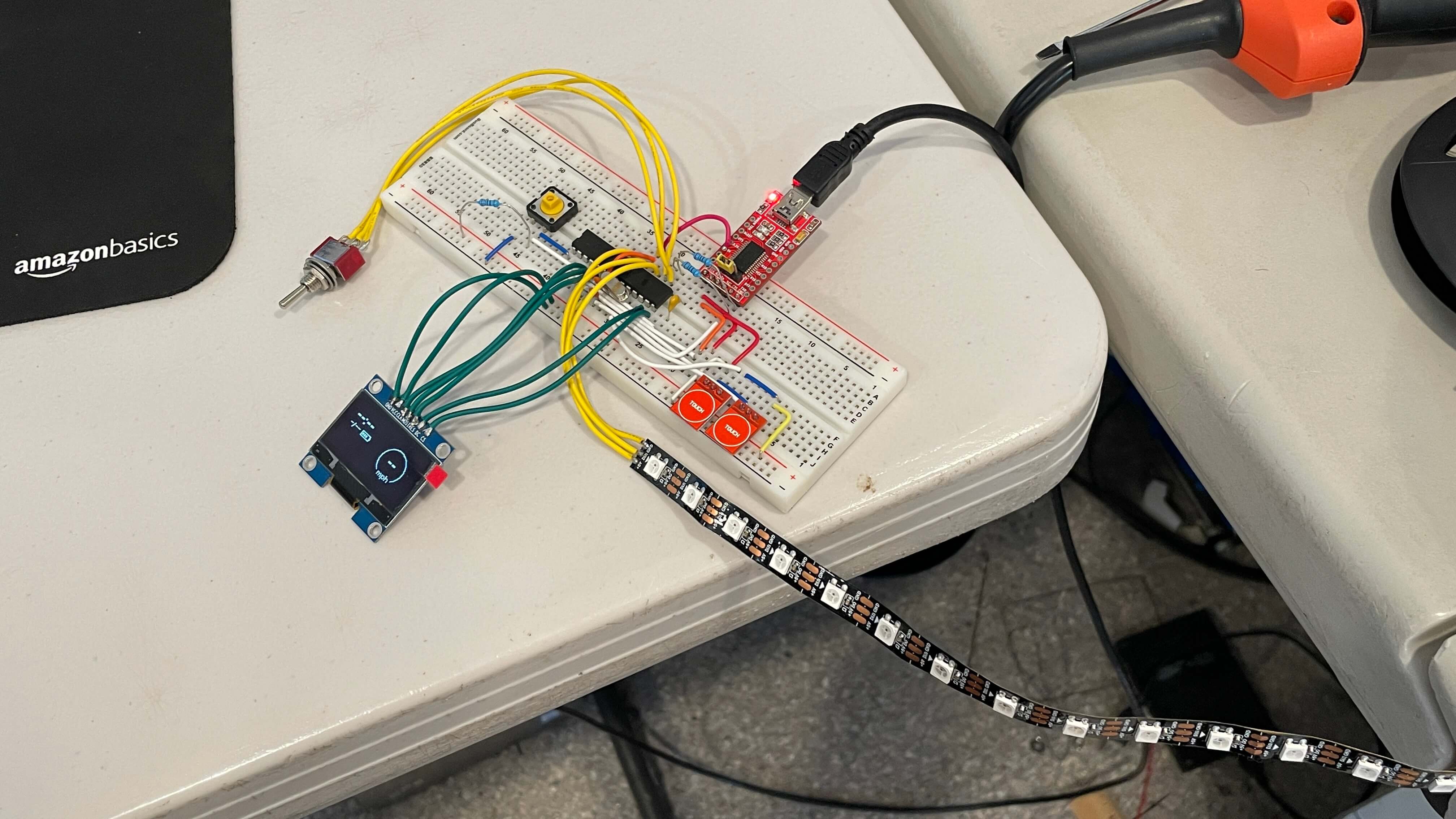

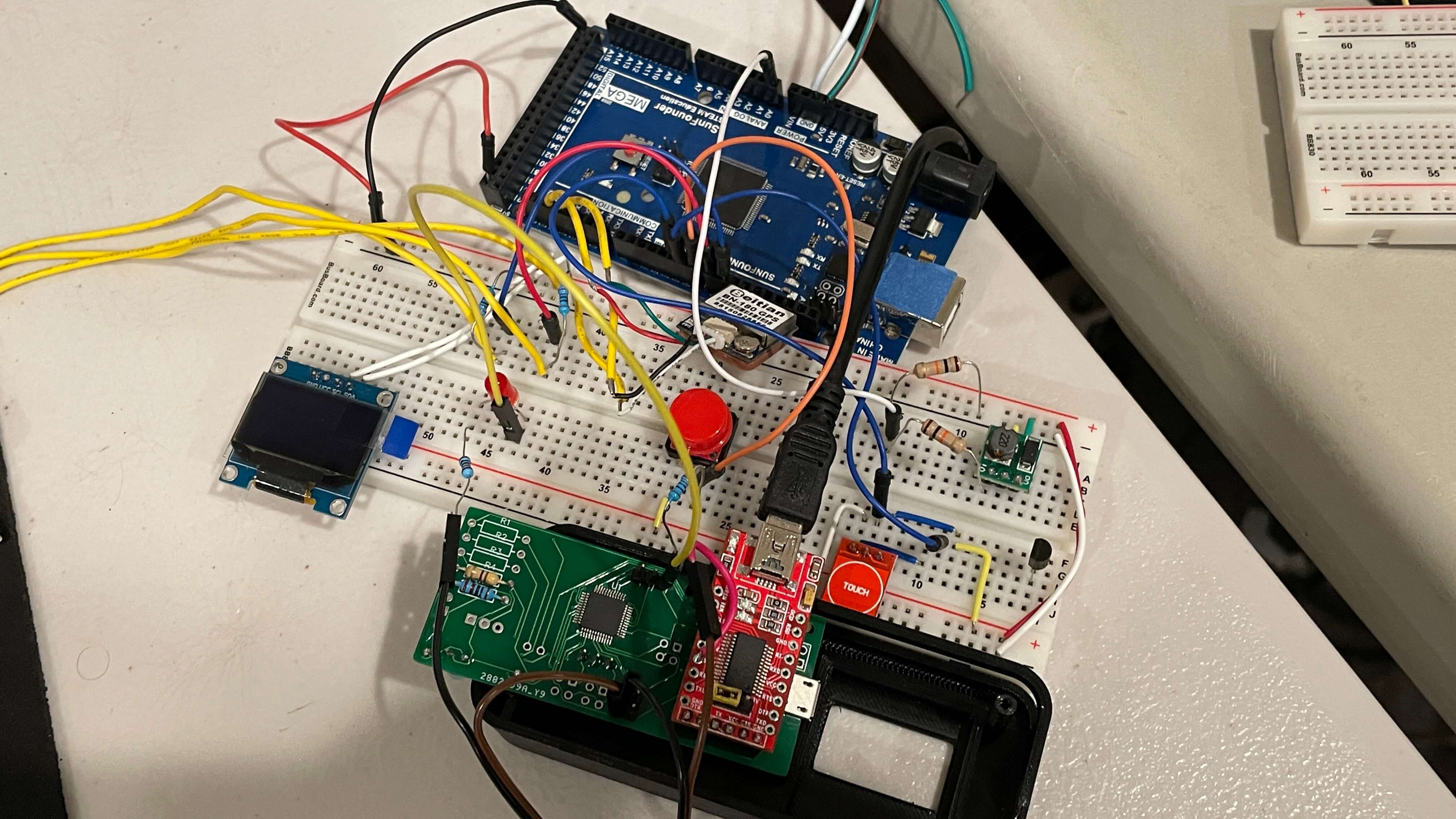

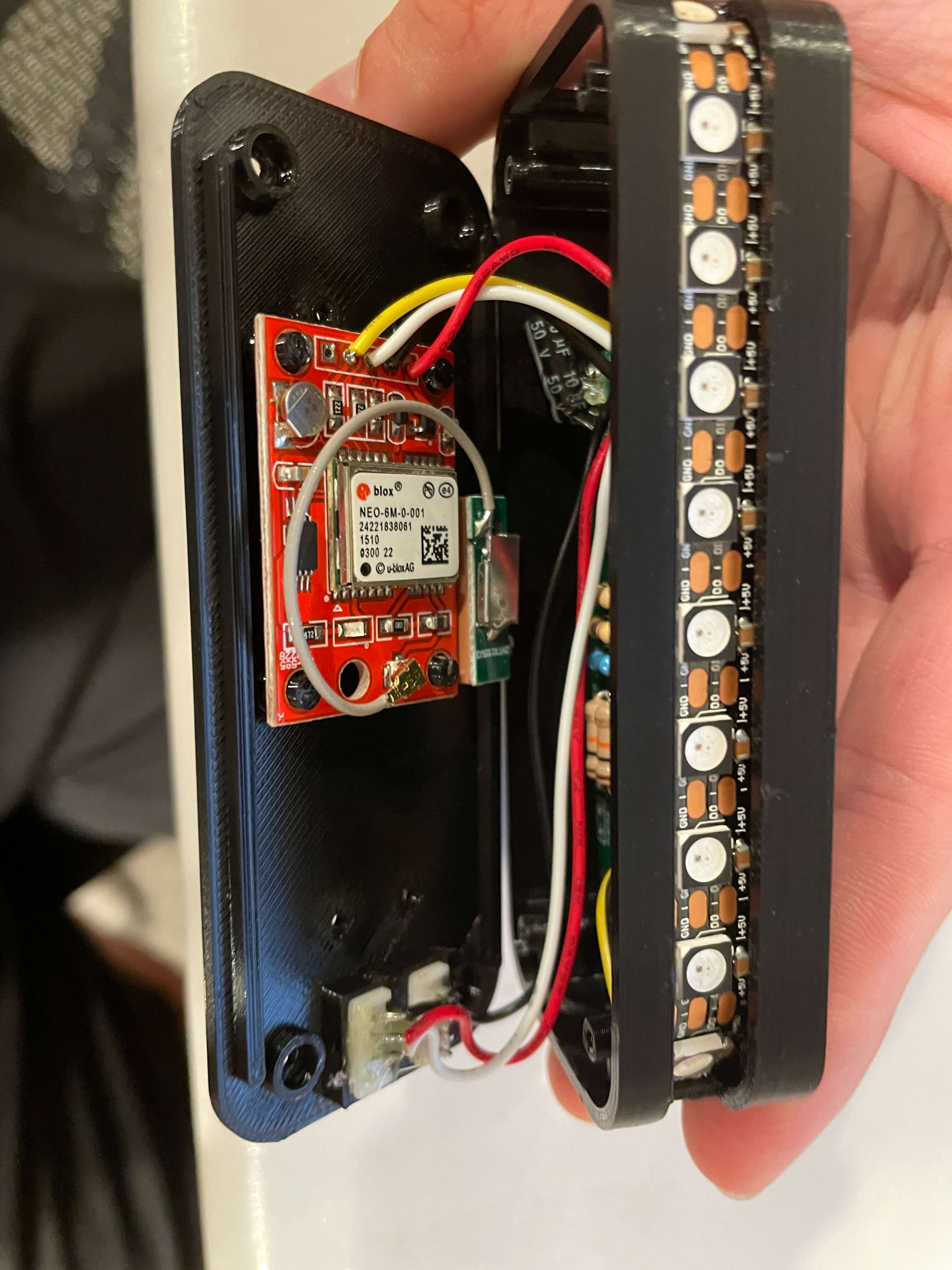

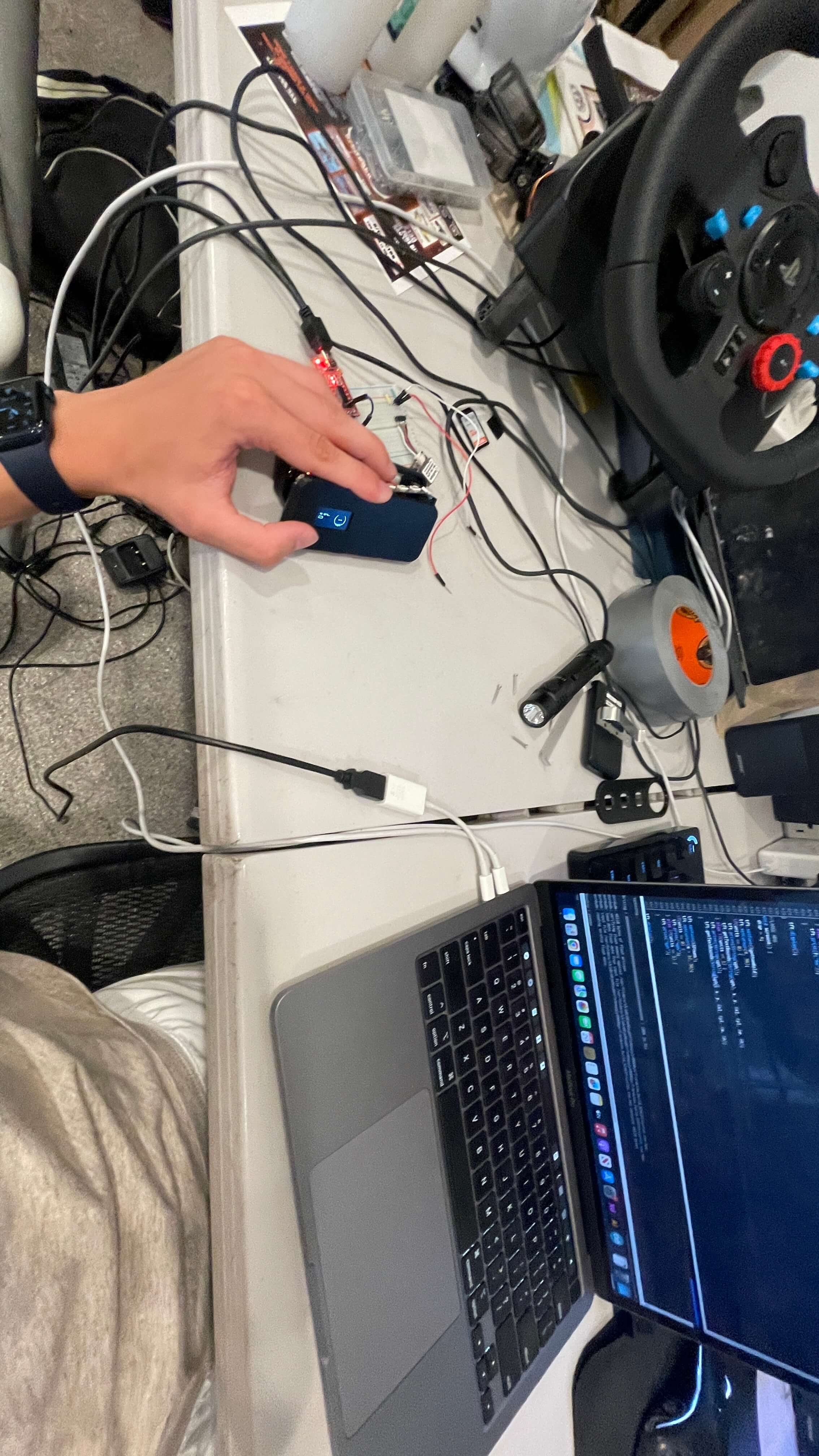

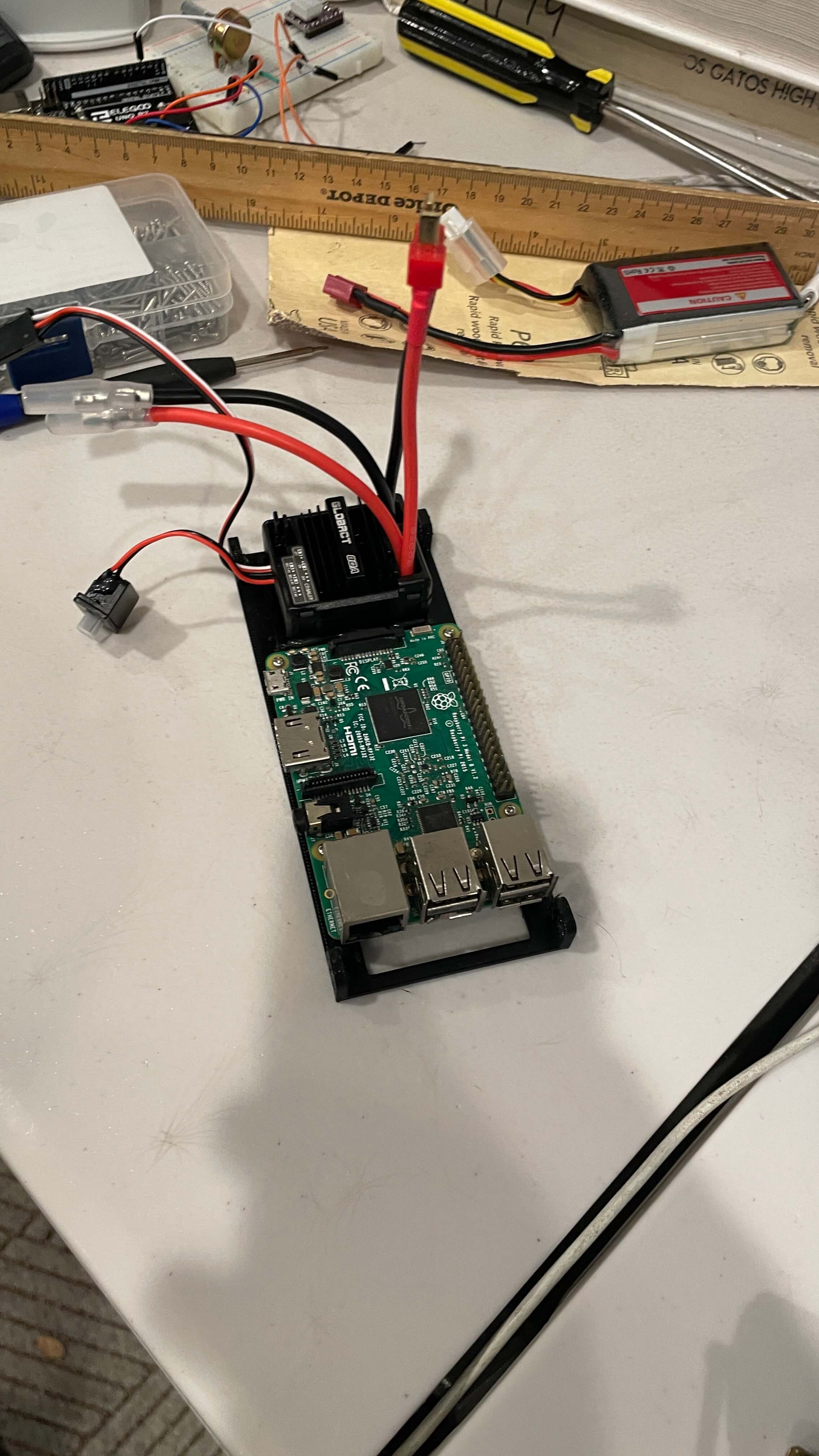

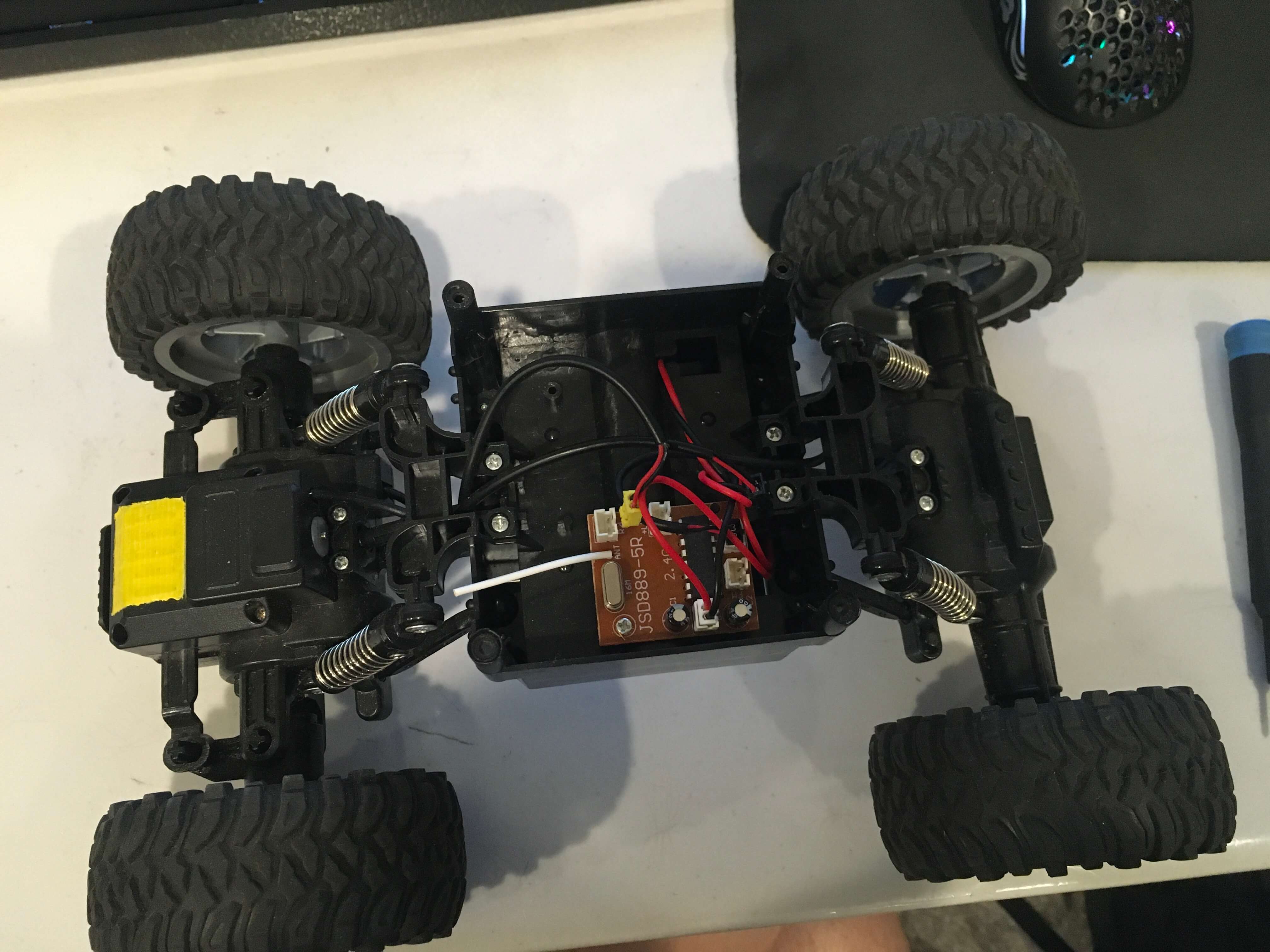

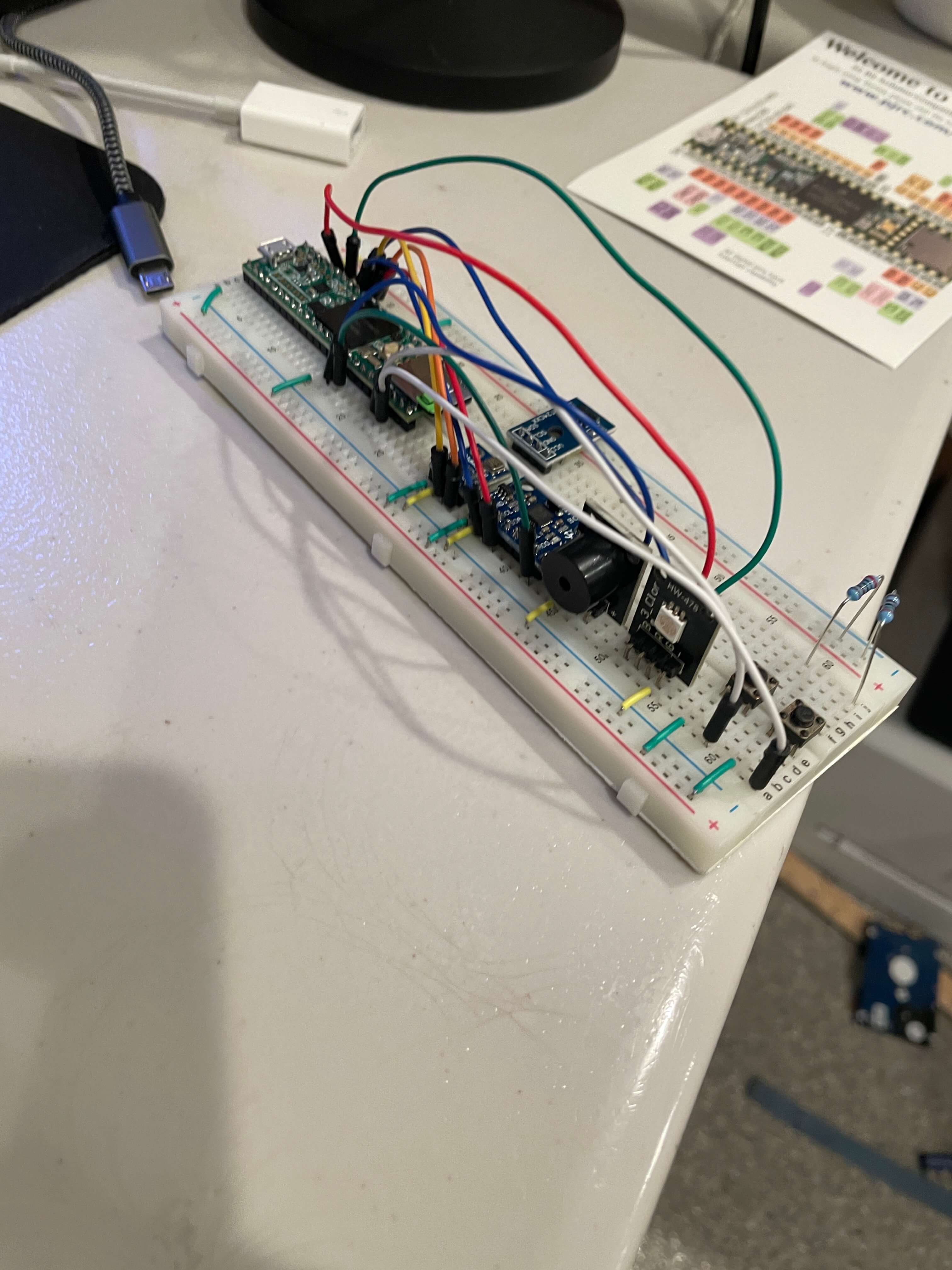

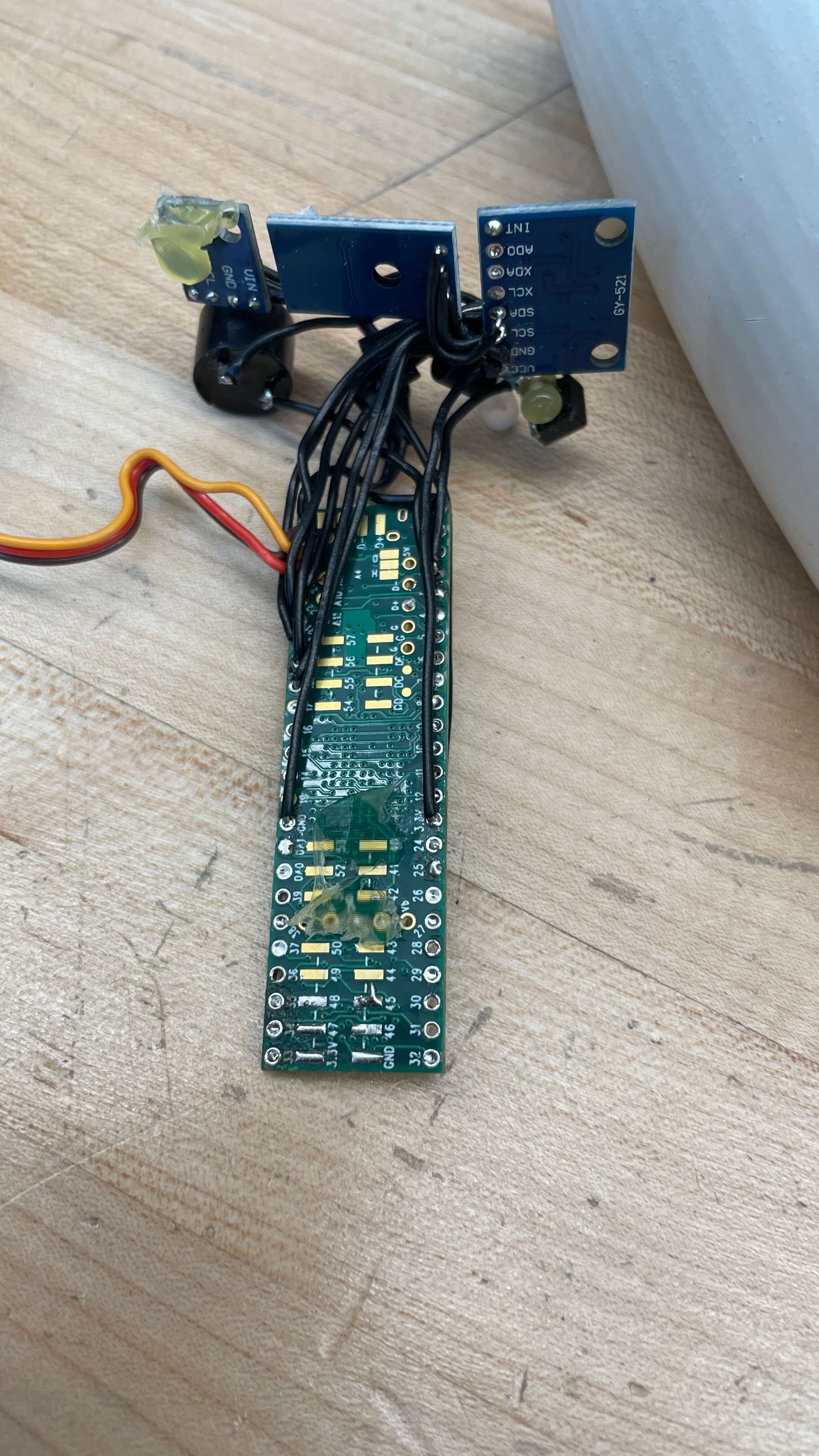

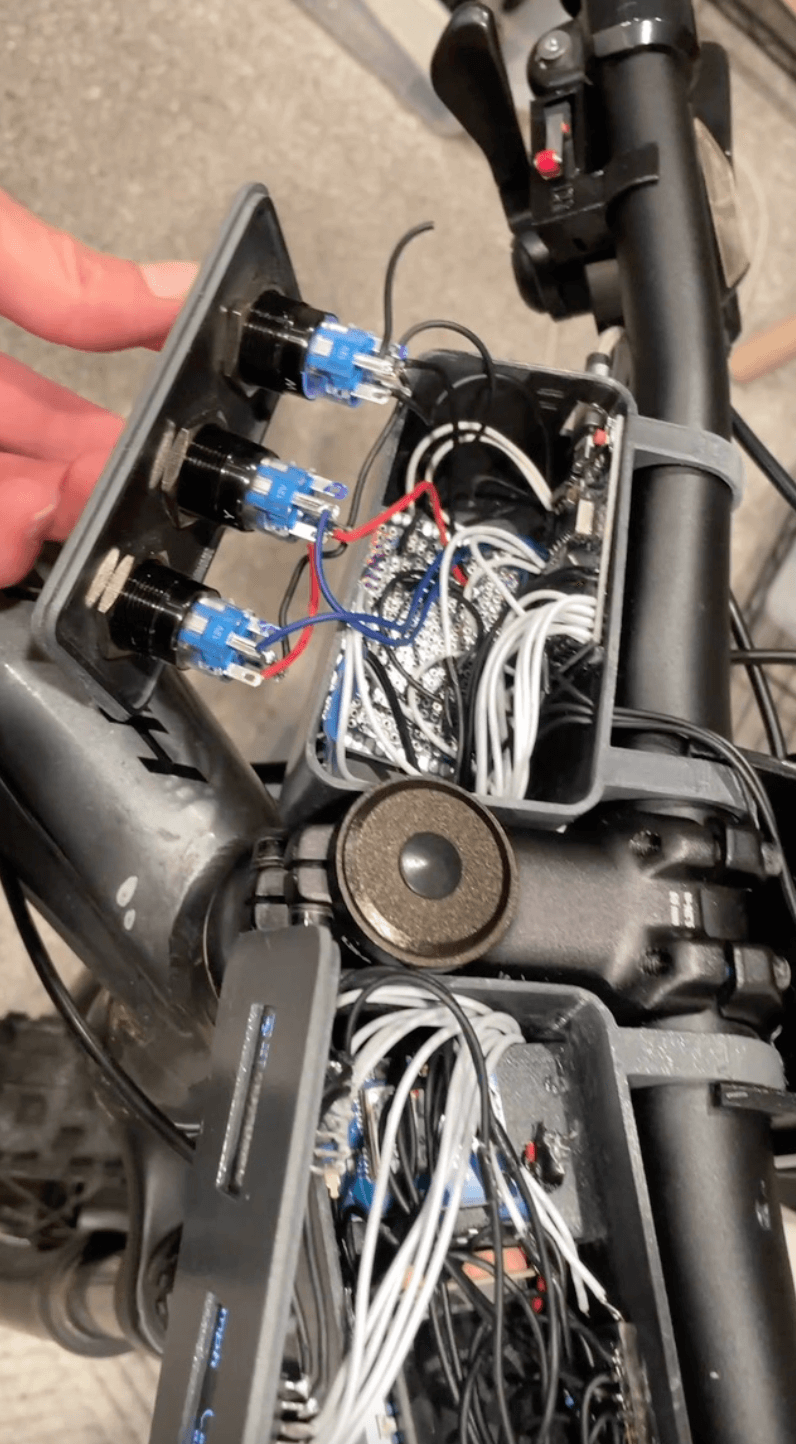

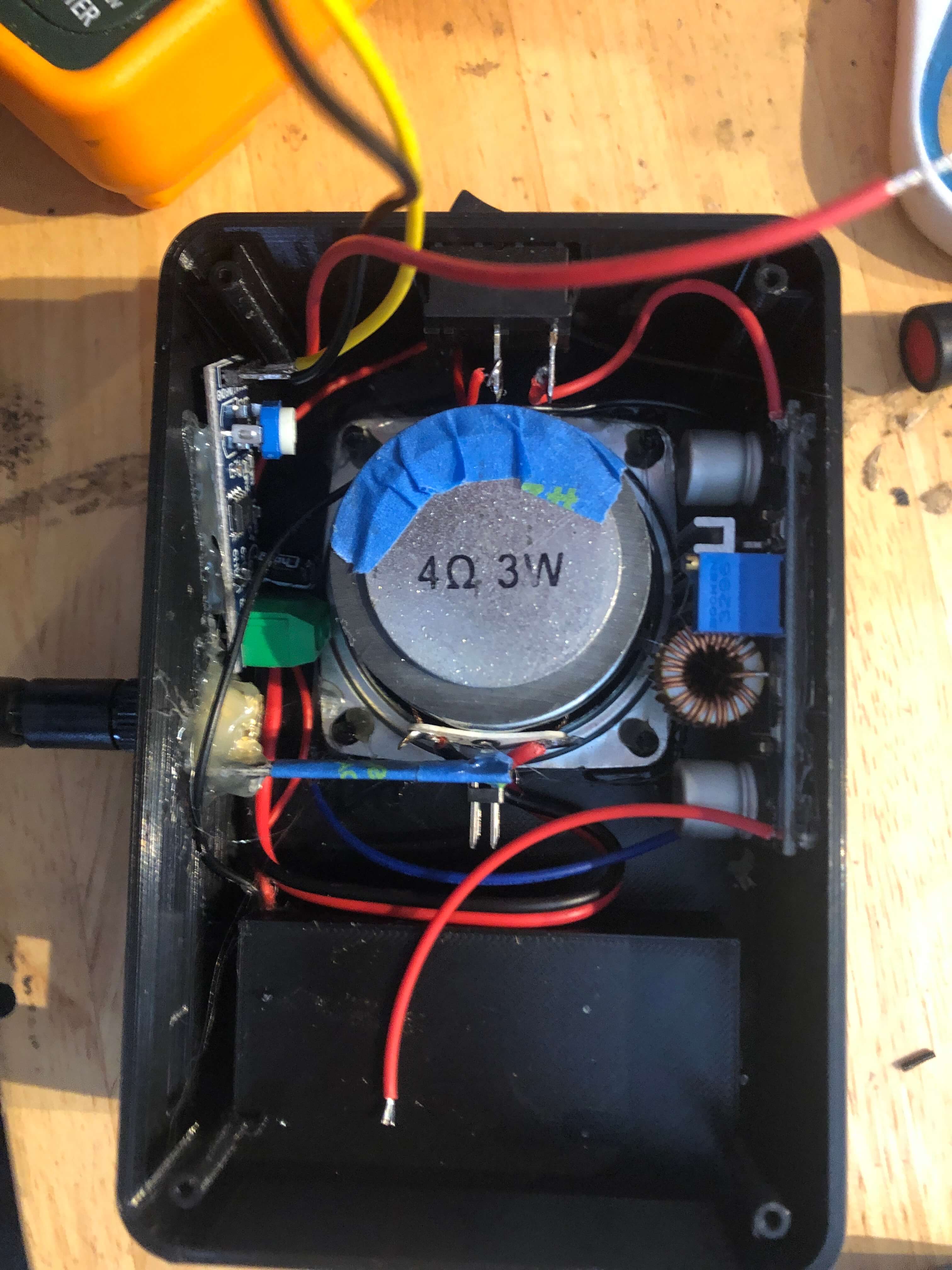

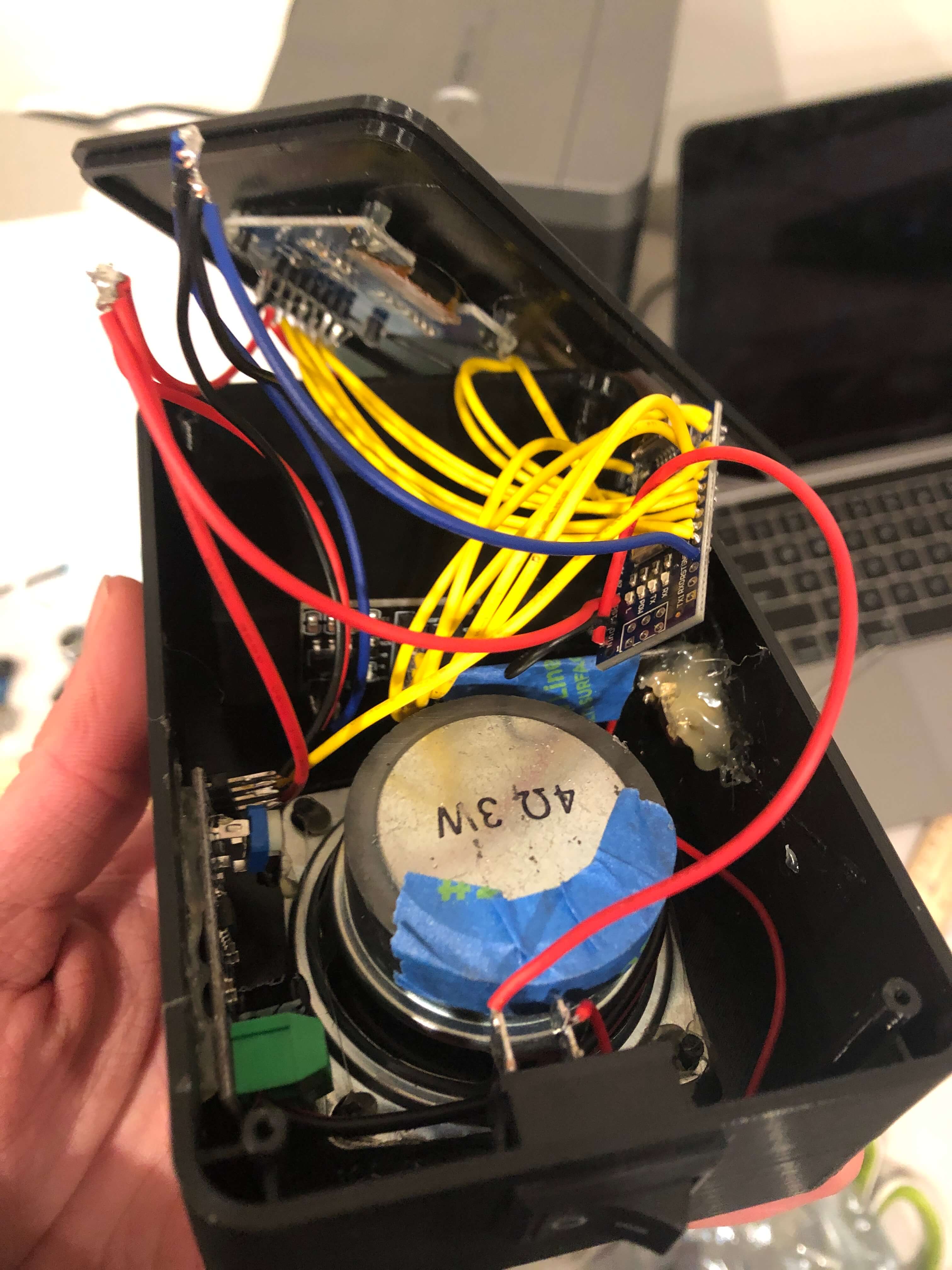

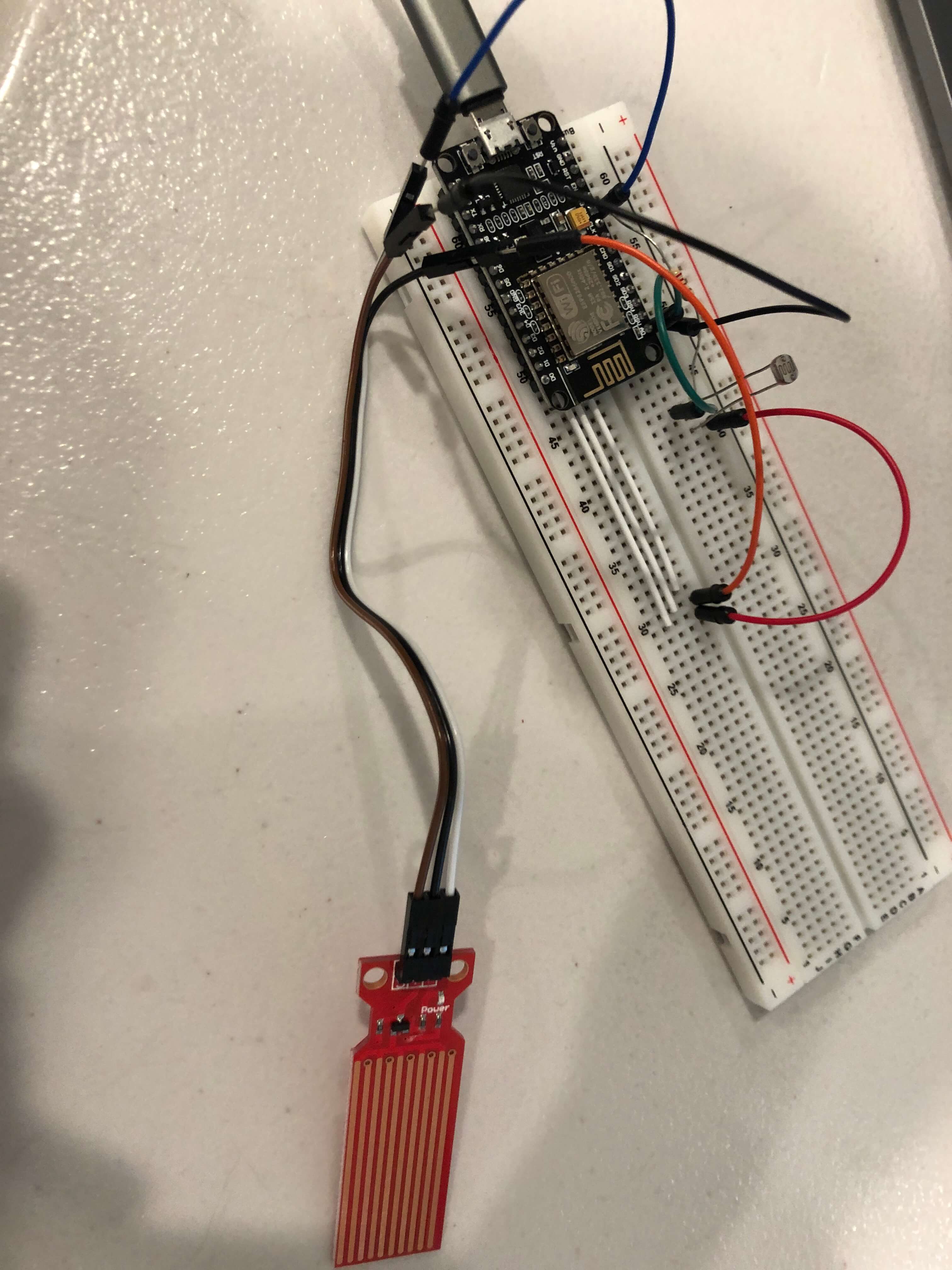

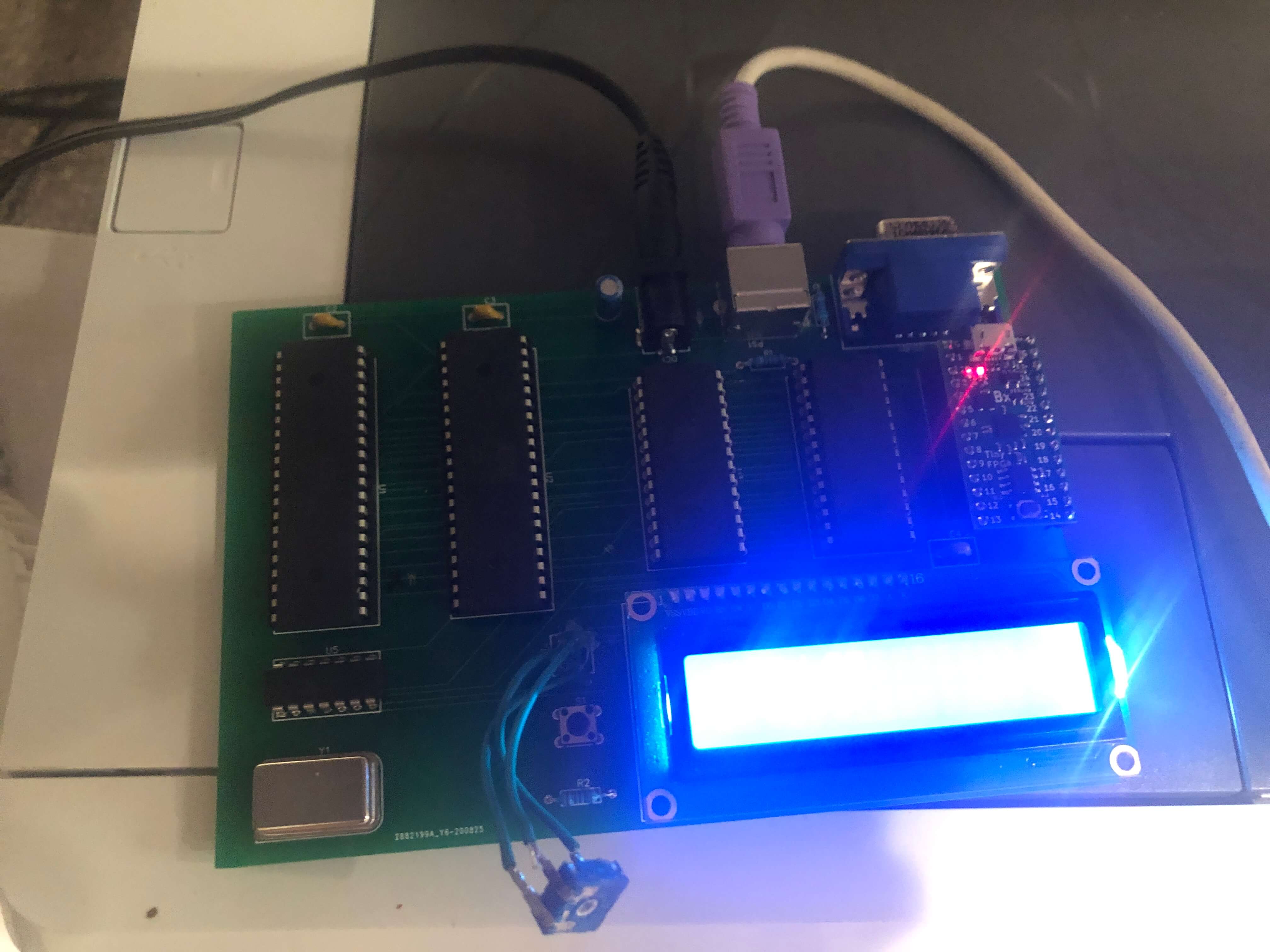

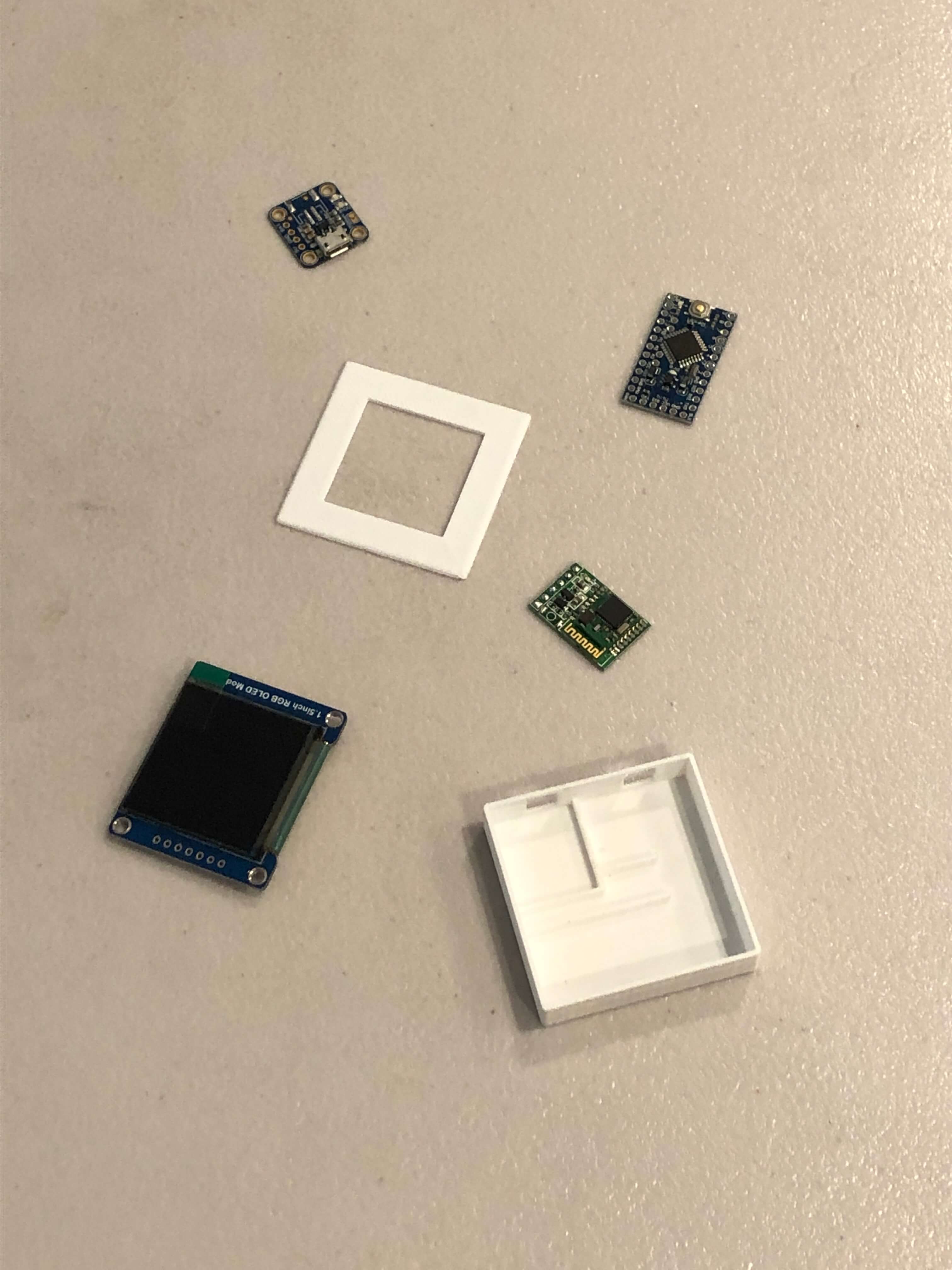

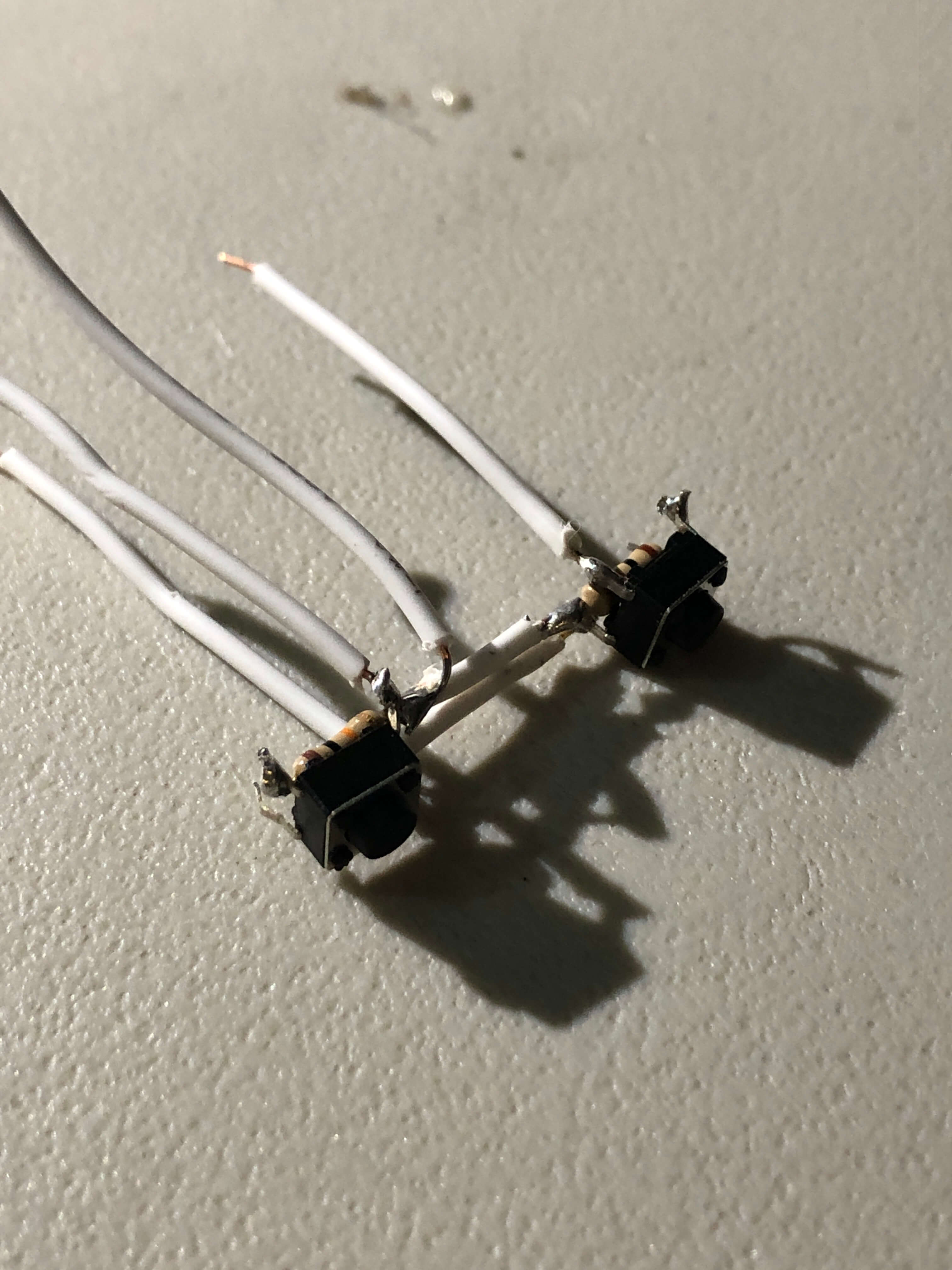

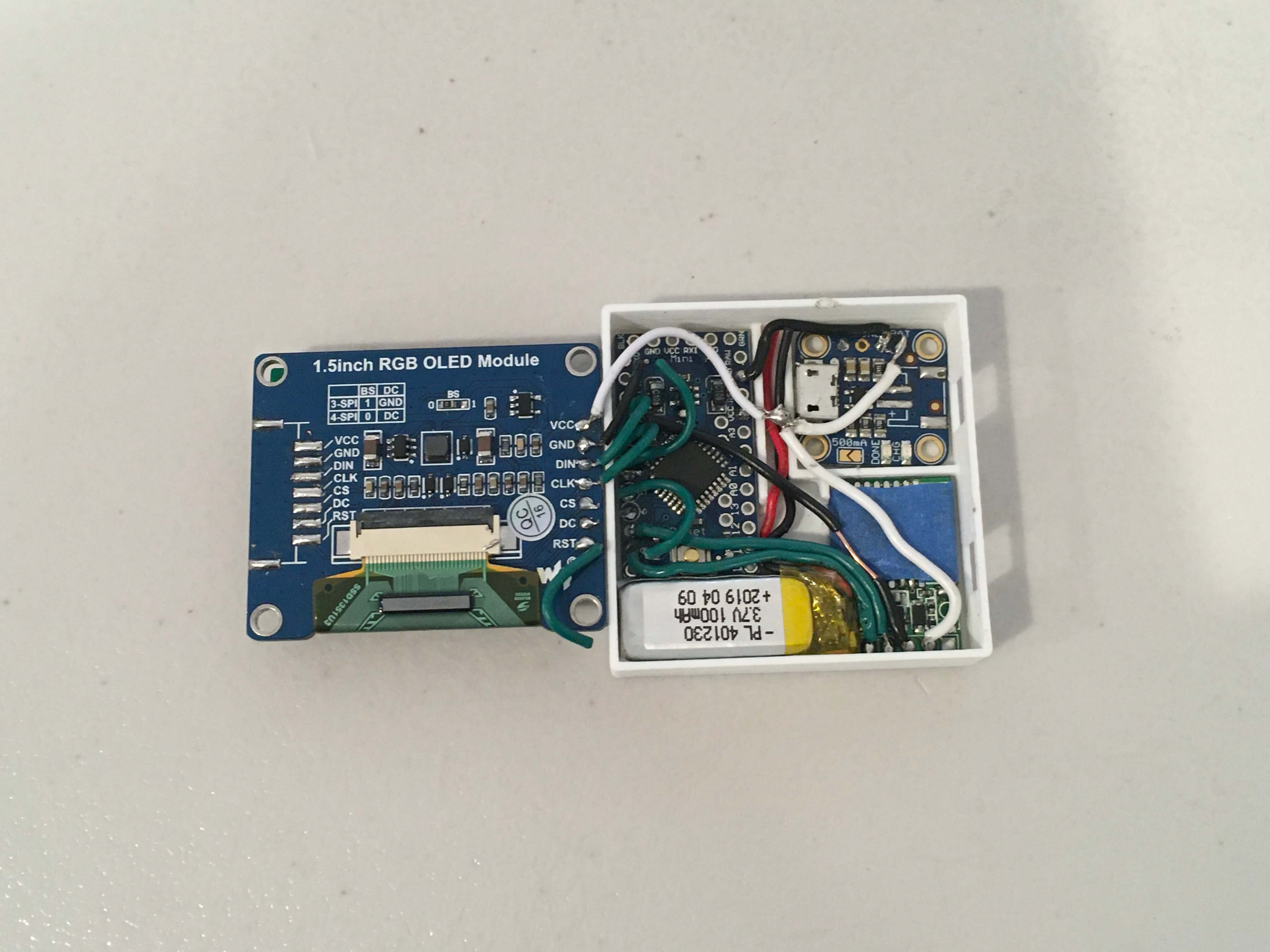

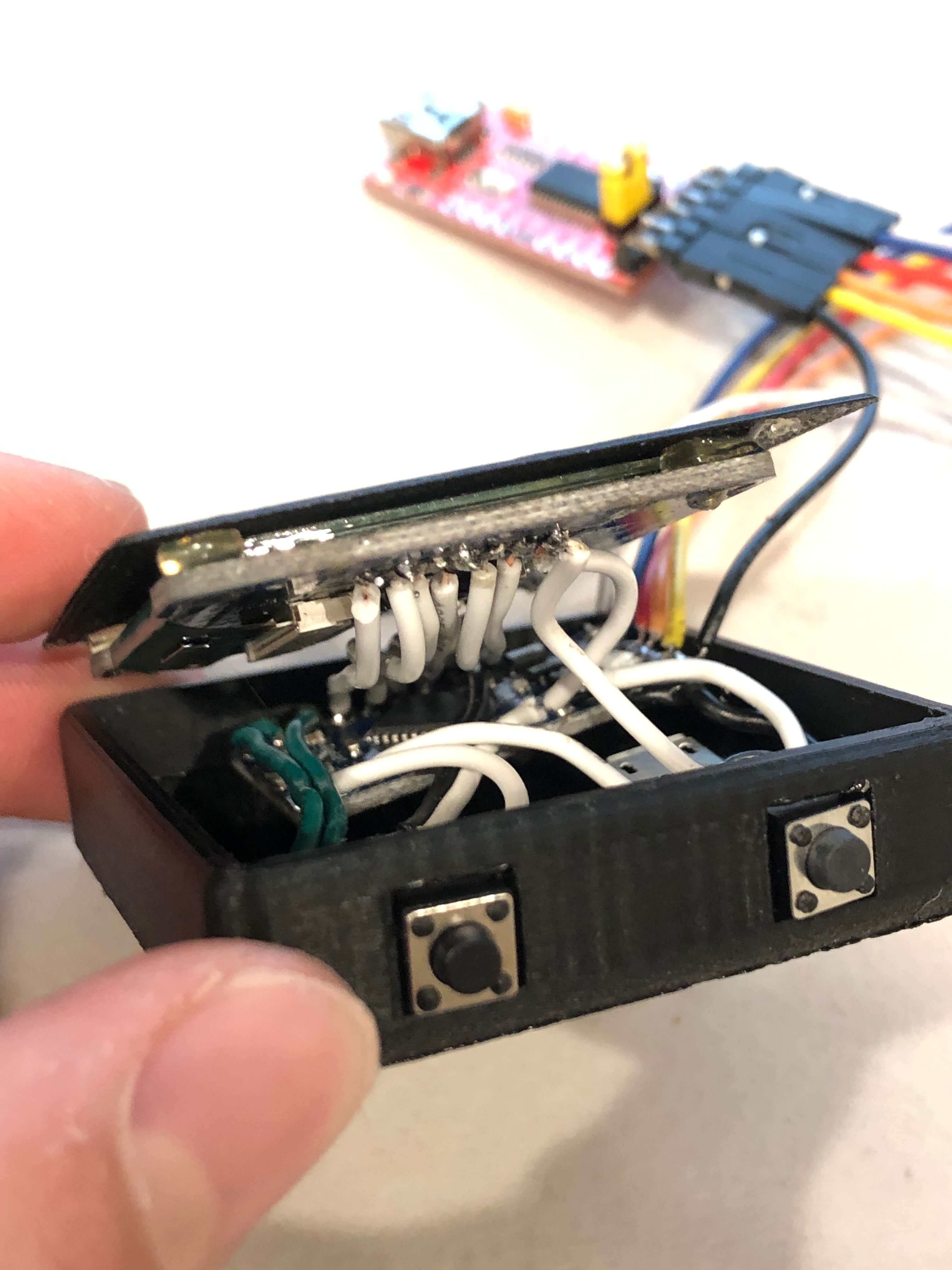

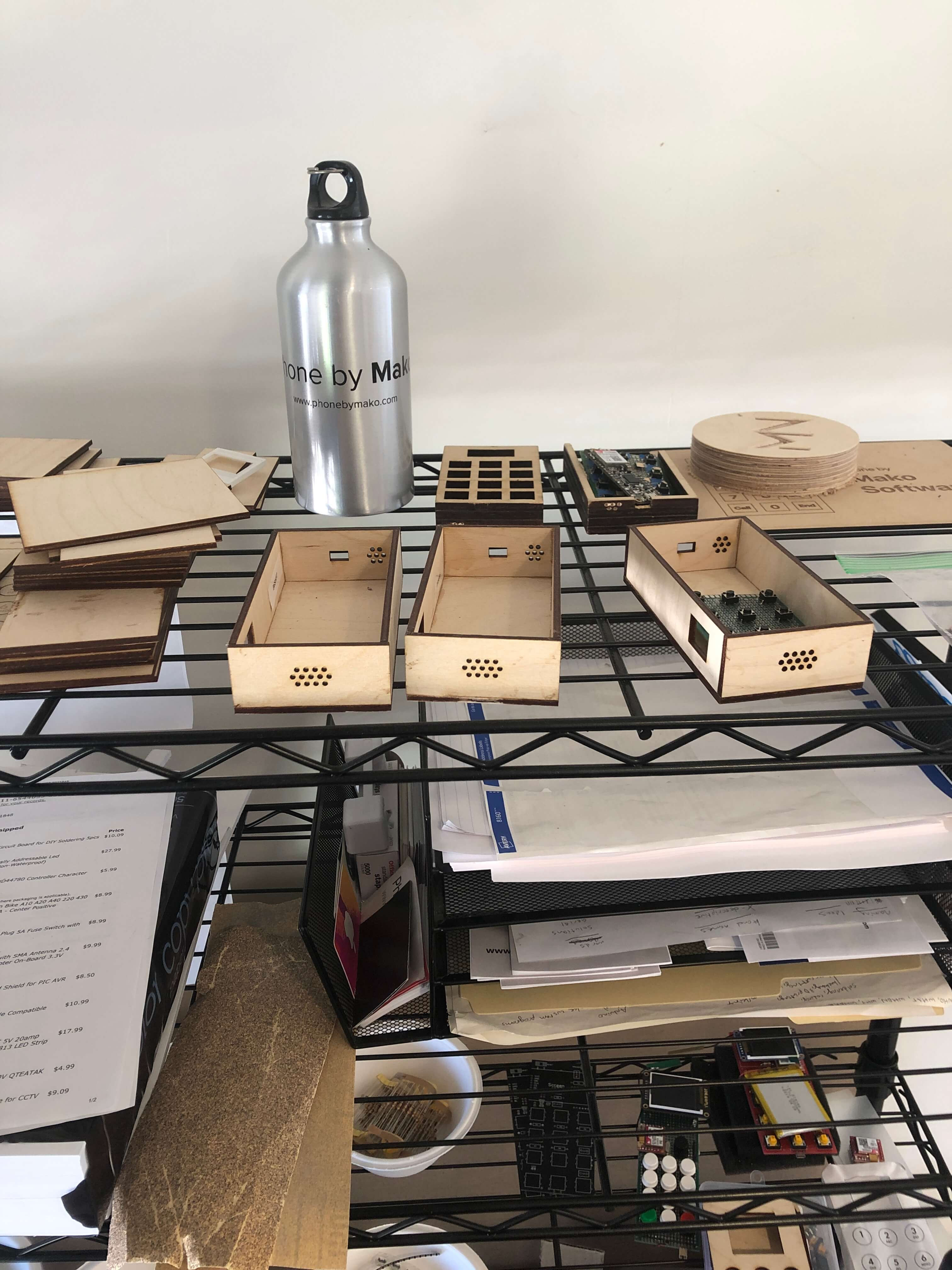

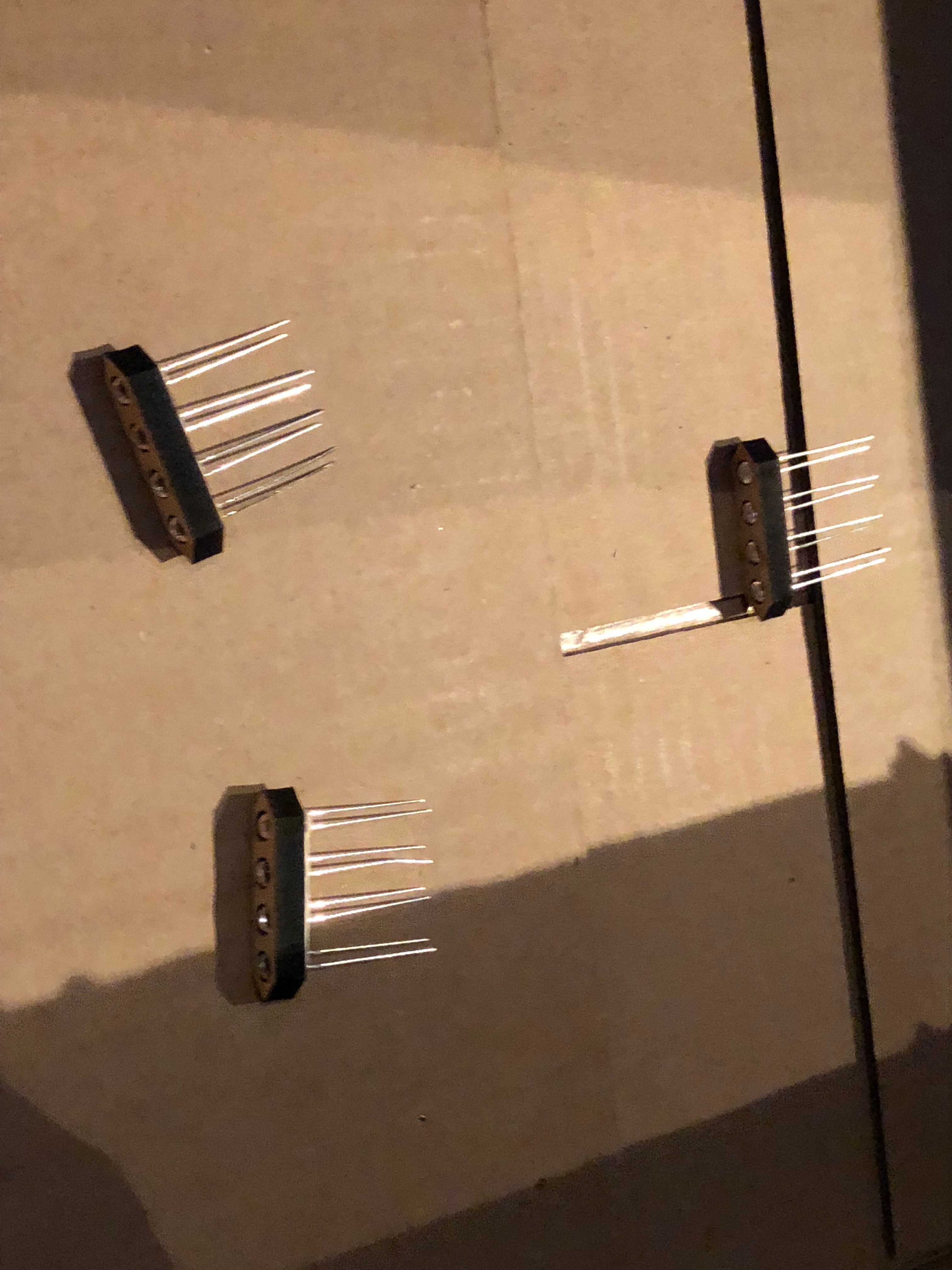

At the heart of Lumle is an ESP8266, which I used because of its built-in WiFi and fast clock speed. Inside the device, there is also a touch sensor and photoresistor (light sensor) to detect the brightness of the room. If the lights are turned off, Lumle will automatically turn off the display. Tapping on the back of Lumle while it is in this sleeping state will bring up a fullscreen clock for a few seconds before shutting off again, and tapping a second time while the clock is active will bring up the regular display.